3D Printing or Additive Manufacturing Service

3D Printing: Advanced Additive Manufacturing Technology

3D printing, also known as additive manufacturing, is an advanced rapid prototyping technology. It creates objects layer by layer using adhesive materials, such as powdered metal or plastic, based on CAD models or digital 3D designs. This process enables the production of complex geometries, customized solutions, and lightweight structures that are difficult to achieve with traditional manufacturing methods.

At TONGDA LINK, we provide comprehensive additive manufacturing services using cutting-edge 3D printing technologies, including:

- Stereolithography (SLA): Ideal for high-resolution and detailed parts using photopolymer resins.

- Selective Laser Sintering (SLS): Utilizes powdered materials to create durable and functional prototypes or end-use parts.

- Fused Deposition Modeling (FDM): A cost-effective solution for rapid prototyping and low-volume production.

- PolyJet Printing: Delivers precise, multi-material, and multi-color prototypes.

- Direct Metal Laser Sintering (DMLS): Produces intricate metal components for demanding applications.

Our services cater to a wide range of industries, supporting not only prototyping but also the direct manufacturing of end-use products.

How Does 3D Printing Work?

3D printers work basically the same as traditional printers. The 3D printer mainly designs a complete three-dimensional three-dimensional model on the computer before printing, and then prints it out. 3D printing molding, like laser molding technology, uses layered processing and superimposed molding to complete 3D solid printing.

The 3D printing process of each layer of 3D printing(Additive Manufacturing) technology is divided into two steps. First, a layer of special glue is sprayed on the area to be formed. The glue droplet itself is small and difficult to spread. Then spray a uniform layer of powder, which will quickly solidify and bond when it encounters glue.

Whereas the areas without glue remain loose. In this way, under the alternation of one layer of glue and one layer of powder, the solid model will be “printed” and formed. After printing, just sweep away the loose powder to plan out the model, and the remaining powder can be recycled.

Selective Laser Sintering

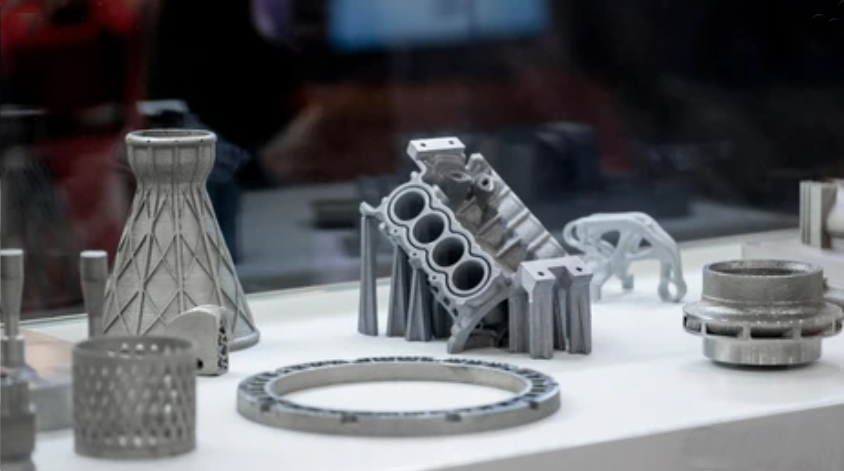

SLS Printing, 3D-printed mechanical part

Metal 3D Printing

DMLS Printing, industrial use prototypes

Stereolithography Printing

SLA Printing, printed plastic craft product

3D PRINTING POST-PROCESSING

Cleaning and curing: After printing, the object is cleaned (such as removing support structures, uncured resin, etc.). Some technologies (such as SLA) also require secondary curing to improve mechanical properties.

Surface treatment: Including sanding, painting, coloring and other steps, aimed at improving the appearance and further improving the performance of the product.

3D PRINTING TO REMOVE SUPPORT STRUCTURES

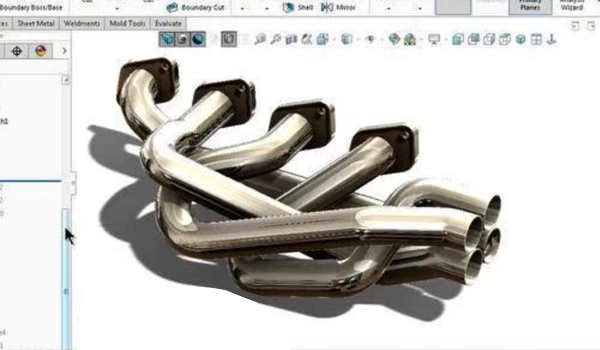

3D metal printing application in the Sports car exhaust manifold parts prototyping

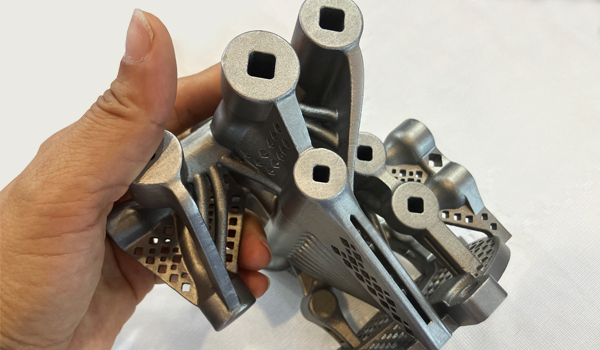

3D metal printing application in the Sports car exhaust manifold valve parts prototyping

3D PRINTING METAL MATERIALS

Main 3D Printing Metal Materials Metal 3D printing utilizes various materials, including titanium alloys, stainless steels, tool steels, aluminum alloys, and high-temperature alloys. These materials find widespread application across aerospace, automotive, medical, and mold manufacturing industries.

• Titanium Alloys (e.g., TA1, TC4, TA15): Valued for high strength, excellent corrosion resistance, and biocompatibility. Primarily used in aerospace components and medical implants.

• Stainless Steels (e.g., 316L, 17-4 PH, 304L): Offer strong corrosion resistance and are well-suited for producing complex parts in small batches.

• Tool Steels: Known for exceptional hardness and wear resistance. Commonly used in injection molds, tooling, and demanding aerospace components.

• Aluminum Alloys (e.g., AlSi10Mg, Al7075): Provide a favorable strength-to-weight ratio and good corrosion resistance. Widely applied in automotive and general industrial components.

• High-Temperature Alloys (e.g., Nickel-based: GH4169/Inconel 718; Cobalt-based): Engineered to withstand extreme heat and stress. Essential for critical parts in jet engines, turbines, and other high-temperature environments.

METAL 3D PRINTING:

Metal 3D printing, a form of additive manufacturing (AM), constructs metal objects layer by layer from digital models.

APPLICATIONS:

Metal 3D printing excels in industries requiring complex, lightweight, or customized components:

- Turbine blades, fuel nozzles (e.g., GE’s LEAP engine), and lightweight brackets.

- Benefits: Weight reduction, improved fuel efficiency, and part consolidation.

- Custom implants (e.g., orthopedic, cranial) and prosthetics.

- Dental devices (crowns, bridges) with patient-specific designs.

- Lightweight components (e.g., engine parts, heat exchangers) for electric vehicles.

- Prototyping and high-performance racing parts.

- Molds with conformal cooling channels for faster production cycles.

- Or, if the mold cavity/core is hard to machine, metal 3D printing is essential.

- Custom jigs and fixtures for assembly lines.

- Turbine components, heat exchangers, and nuclear reactor parts.

- Enables complex geometries for efficient energy systems.

- Durable, lightweight components for military vehicles and aerospace.

- On-demand spare parts in remote locations.

- High-end custom jewelry and luxury items.

- Performance gear (e.g., bicycle frames, sporting equipment).