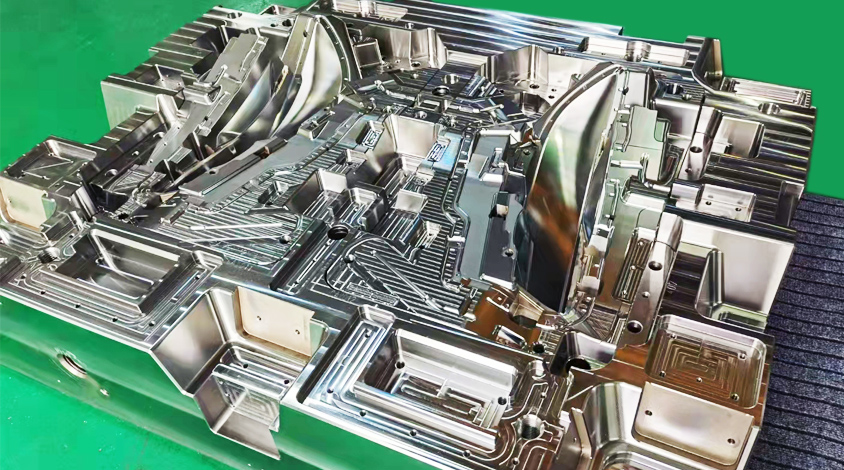

Plastic Mold Design & Manufacturing

TONGDA LINK makes plastic molds for automotive parts, medical device, consumer electronics, industrial plastic parts and etc. Specializing in the manufacturing of high-precision molds such as automotive lights, bumpers, decorative trims, LED lens, medical tips, medical centrifuge tubes, etc.

TONGDA LINK has 8 plastic mold engineers and 25 skilled mold-making technicians who are good at making precise plastic molds.

The main steel suppliers of TONGDA LINK are LKM, Gröditz and ASSAB. We will choose USA and Japan steel for mold manufacturing according to mold requirements. Due to our reliable steel supplier, skilled technicians and high-end precision mold manufacturing equipment, our mold quality is guaranteed.

TONGDA LINK’s mold manufacturing capacity is 370 sets of molds a year, and the automotive industry accounts for about 40%, followed by related molds for medical equipment and consumer electronics products.

Our engineers design plastic mold according to plastic part features, the mold will be 2 PLATE MOLD, 3 PLATE MOLD, PIN-POINT GATE MOLD, HOT RUNNER MANIFOLD mold, THROUGHLY HARDEN mold (above 44HRC), PRE-HARDENED mold (below 44HRC).

The hot runner system we used for mold manufacturing are DME, MOLD-MASTER, SYNVENTIVE, HUSKY, INCOE, YOUDU, SM, and etc.

Plastic mold manufacturing process–EDM

EDM has high precision, can achieve machining accuracy of ±0.004mm to ±0.002mm; WEDM can reach ±2.5um machining accuracy, and roughness can also reach 0.15-0.2uRa; CNC surface finish can reach 0.29µRa, and small machine tools can reach 0.8µRa.

Different EDM machines have different performance, TONGDA LINK updates the equipment every year to ensure higher quality mold manufacturing.