Plastic Injection Molding Production

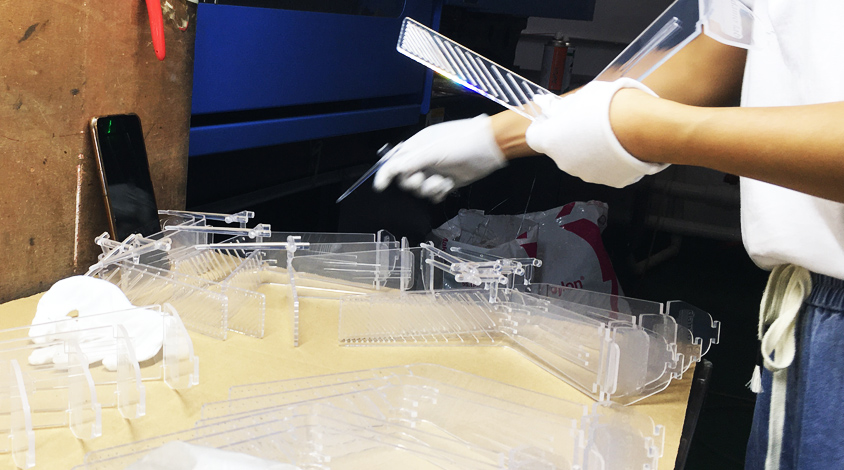

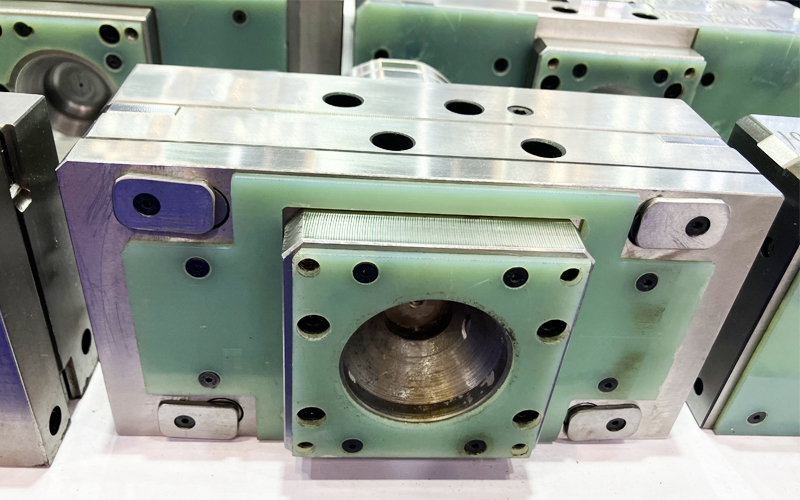

TONGDA LINK Mold is your trusted partner for end-to-end plastic manufacturing solutions. We specialize in high-precision custom mold design and manufacturing, injection molding services, and rapid prototyping, delivering seamless support from concept to mass production. Our expertise ensures cost-effective, scalable, and high-quality plastic components tailored to your unique requirements.

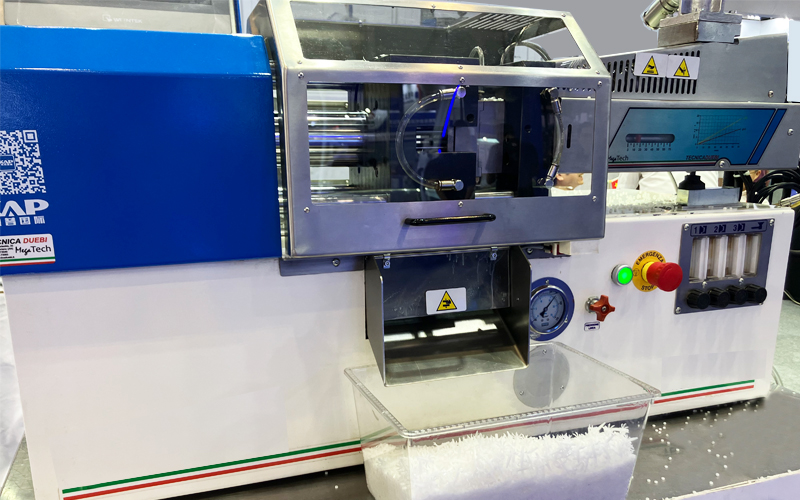

AT TONGDA LINK, we are equipped with advanced plastic injection molding machines capable of supporting high-volume production for a diverse range of applications. By leveraging our production facilities in China, we help customers significantly reduce costs, particularly amidst the rising energy expenses in Europe. Our efficient operations and focus on quality enable us to deliver high-value solutions that create tangible benefits for our customers.

TONGDA LINK’s Strict Quality Control for Injection Molding Production

At TONGDA LINK, we adhere to stringent quality control measures throughout the injection molding production process, to ensuring that the molded parts meet the required specifications and standards. Here’s a breakdown of how we control quality during this phase:

| 1. Raw Material Verification | 5. Post-Production Quality Checks |

| Material Certification; | Full Inspection for Critical Parts; |

| Pre-Drying. | Functionality Testing. |

| 2. Machine Setup and Process Parameter Control | 6. In-Process Inspection |

| Optimal Machine Setup; | Dimensional Checks; |

| First-Article Inspection (FAI); | Visual Inspection; |

| Automated Monitoring. | Sampling Plan. |

| 3. Process Control Documentation | 7. Documentation and Traceability |

| Control Charts; | Batch Tracking; |

| Mold Condition Monitoring. | Record-Keeping. |

| 4. Continuous Improvement | 8. Preventive Maintenance |

| Feedback Loop; | Regular Machine and Mold Maintenance; |

By following these quality control measures, TONGDA LINK ensures that every injection molded part is consistent, precise, and meets the highest standards.

TONGDA LINK possesses the specialized expertise and advanced machinery required for engineering-grade injection molding, challenging high-temperature thermoplastic materials molding like PEEK, PEI, and PPS

TONGDA LINK`s proven process ensures integrity and precision for high-temperature polymers–PEEK, achieving the exceptional mechanical properties your critical application demands.

PPS ( polyphenylene sulfide )

PPS (polyphenylene sulfide) is a high-performance engineering plastic renowned for its excellent heat resistance, chemical resistance, and mechanical properties, making it essential for electronics, automotive parts, and the chemical industry.

PPS INJECTION MOLDING

Achieving consistent quality in PPS injection molding requires meticulous control of process parameters like temperature, pressure, and time due to its inherent complexity. Leveraging deep expertise gained from years of mold manufacturing and PPS production, TONGDA LINK offers a detailed analysis of the PPS injection molding temperature range and its crucial influence on final part quality.

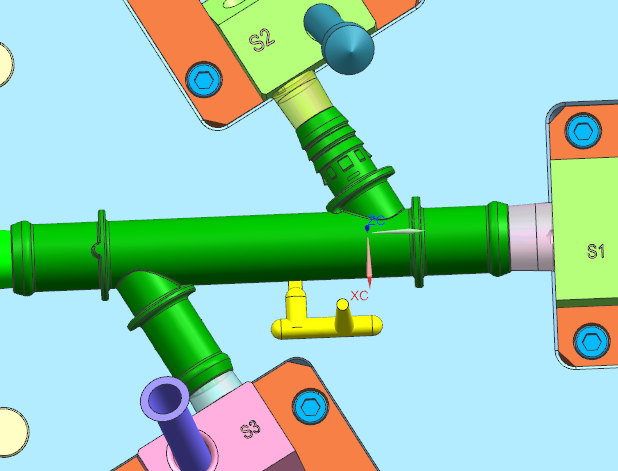

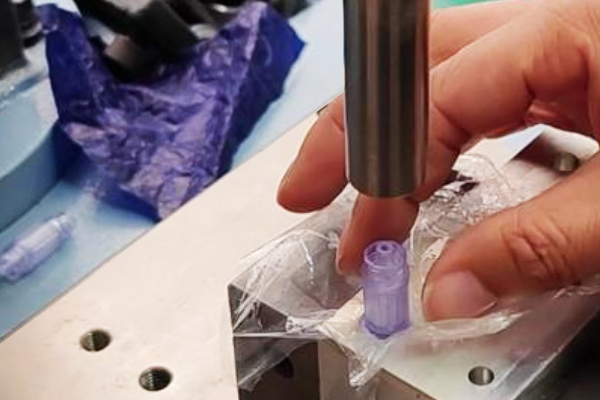

MICROINJECTION MOLDING PRODUCTION

TONGDA LINK leverages advanced microinjection molding technologies to reduce manufacturing costs for precision plastic components, empowering customers to achieve greater cost-efficiency and profitability.

Mold lifetime: 1,000,000 shots

Cavities: 1×6

Mold leadtime: 3 weeks

-

Produces ultra-small, intricate parts with tolerances as tight as ±0.001 mm, ideal for industries like medical devices, microelectronics, or optics where tiny, high-precision components are critical.

-

Minimizes material waste by using exact-shot volumes, reducing raw material costs (especially important for expensive engineering-grade resins or biocompatible plastics).

-

Ensures consistent part quality across large production runs, crucial for industries requiring uniformity (e.g., automotive sensors, microfluidic chips).

-

Lowers per-unit costs for mass production of small parts by automating processes and reducing labor-intensive post-processing.

-

Enables micro-scale features (thin walls, micro-channels, threads) that traditional molding cannot achieve, unlocking innovative product designs.

-

Parts often require minimal finishing (e.g., no trimming or deburring), saving time and labor costs.

-

Works with engineering-grade polymers, liquid silicone rubber (LSR), and even biodegradable plastics, offering flexibility for diverse applications.

-

Easily transitions from prototyping (low volumes) to full-scale production, supporting rapid product development cycles.

APPLICATIONS OF THERMOPLASTICS

Our expertise lies in producing high-quality injection-molded plastic components for a wide range of industries and applications, including:

- Consumer Electronics: Durable and aesthetically pleasing plastic parts.

- Automotive: Inner decorative trims and precise functional components.

- Medical Devices: High-precision parts that meet strict regulatory standards.

- High-Surface-Requirement Products: Parts with exceptional finishes for beauty devices and luxury goods.

- Massagers and Wearables: Functional and visually appealing plastic components.

- Electronics: Housing and functional parts for various devices.

WHAT IS INJECTION MOLDING?

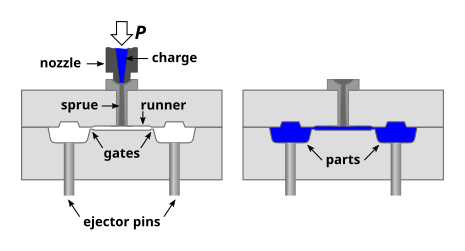

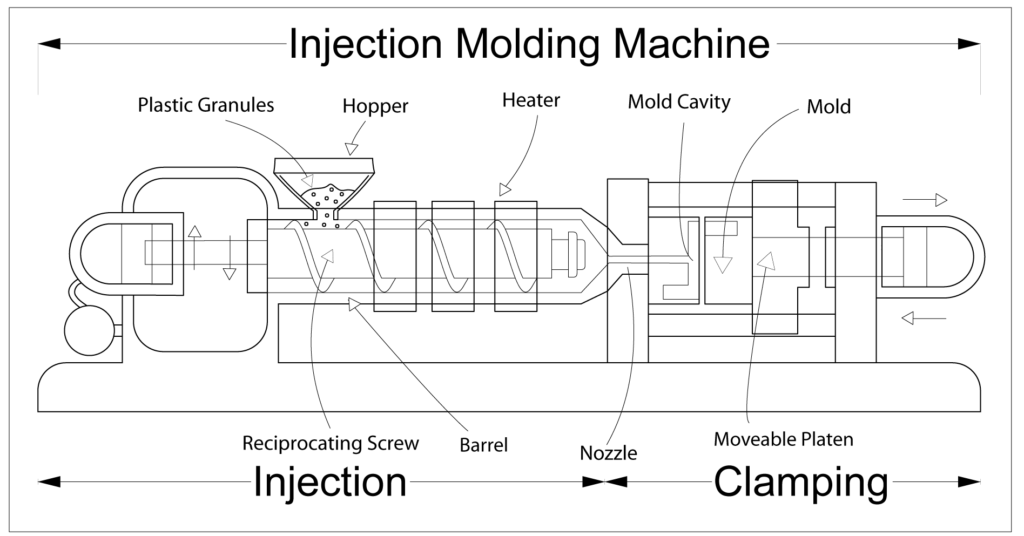

Injection moulding (U.S. spelling: injection molding) is a manufacturing process for producing parts by injecting molten material into a mould, or mold.

By ariel cornejo – Own work, CC BY-SA 4.0, https://commons.wikimedia.org/w/index.php?curid=39782900

Injection molding materials are primarily thermoplastics, but thermosets, elastomers, and specialty polymers are also used. In Injection Molding, polymer granules are first melted and then injected under pressure into a mold, where the liquid plastic cools and solidifies. The thermoplastic polymers used in injection molding can be colored or filled with other additives. The choice depends on the part’s requirements (e.g., strength, flexibility, heat resistance, cost).

By User:Brockey, CC BY 3.0, https://commons.wikimedia.org/w/index.php?curid=21365163

An injection moulding machine

Injection moulding uses a special-purpose machine that has three parts: the injection unit, the mould and the clamp. Parts to be injection-moulded must be very carefully designed to facilitate the moulding process; the material used for the part, the desired shape and features of the part, the material of the mould, and the properties of the moulding machine must all be taken into account. The versatility of injection moulding is facilitated by this breadth of design considerations and possibilities.

https://en.wikipedia.org/wiki/Injection_moulding

DO YOU WANT TO GET A MOLD COST REFUNDED FROM TONGDA LINK?

COMMON MATERIALS FOR INJECTION MOLDING

Recyclable, meltable, and reusable:

-

Polypropylene (PP):

-

Properties: Lightweight, chemical/heat resistant, flexible.

-

Uses: Food containers, automotive parts, toys.

-

-

ABS (Acrylonitrile Butadiene Styrene):

-

Properties: Tough, impact-resistant, glossy finish.

-

Uses: LEGO bricks, electronics housings, automotive trim.

-

-

Polyethylene (PE):

-

HDPE: Rigid, chemical-resistant (bottles, pipes).

-

LDPE: Flexible (plastic bags, squeeze bottles).

-

-

Polycarbonate (PC):

-

Properties: Transparent, heat-resistant, high strength.

-

Uses: Safety goggles, bulletproof glass, medical devices.

-

-

Nylon (PA):

-

Properties: High strength, wear-resistant, absorbs moisture.

-

Uses: Gears, bearings, textiles.

-

-

POM (Acetal/Delrin®):

-

Properties: Low friction, high stiffness.

-

Uses: Precision gears, zippers, automotive components.

-

-

TPE/TPU (Thermoplastic Elastomers):

-

Properties: Rubber-like flexibility.

-

Uses: Seals, grips, phone cases.

-

For demanding applications:

-

PEEK: Extreme heat/chemical resistance (aerospace, medical).

-

Ultem (PEI): Flame-retardant, high strength (electronics, automotive).

-

LCP (Liquid Crystal Polymer): Dimensional stability (microelectronics, connectors).

Irreversibly harden when cured (not recyclable):

-

Epoxy: High strength, electrical insulation (circuit boards, adhesives).

-

Phenolic: Heat/flame-resistant (handles, electrical components).

-

PLA (Polylactic Acid):

-

Compostable, derived from cornstarch (packaging, disposable cutlery).

-

-

PHA (Polyhydroxyalkanoates):

-

Marine-degradable (medical implants, films).

-

Enhance material properties:

-

Glass Fiber: Increases strength/stiffness (e.g., GF-nylon).

-

Carbon Fiber: Lightweight, conductive (automotive, aerospace).

-

Flame Retardants: Improve fire resistance (electronics housings).

-

Colorants: Custom hues for branding or UV protection.

End-to-End Manufacturing Support For Plastic Product Development

Beyond our core injection molding expertise, TONGDA LINK provides comprehensive post-processing solutions designed to reduce costs, streamline production, and accelerate efficiency for both new product development and OEM manufacturing projects.

- Surface Finishing: High-quality texturing, coating, and polishing.

- Plastic Product Secondary Processing: Trimming, welding, and engraving.

- Assembly Services: Seamless integration of components for finished products.

- Packaging Solutions: Custom packaging options to protect and present your products effectively.

Surface Finishing

TONGDA LINK supports painting, electroplating to achieve premium textures, coatings, and appearances for new product development.

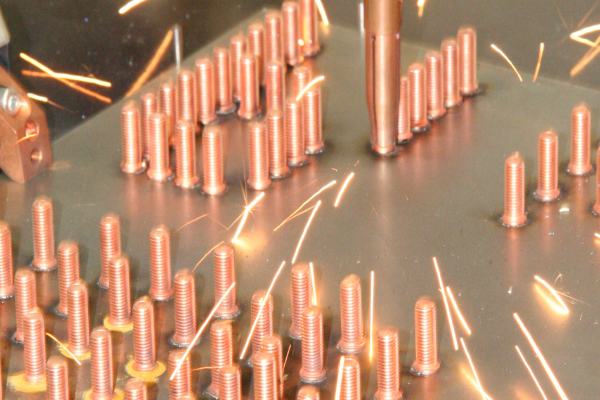

Ultrasonic Welding and Hot Melt Welding

Reliable joining techniques for complex assemblies.

Trimming and Screwing

TONGDA LINK support trimming and screwing to achieve a precise finishing and assembly for product development and manufacturing.

Laser Engraving

TONGDA LINK supports laser engraving to help customers make custom markings, logo and branding with precision.

Custom Packaging

TONGDA LINK offers custom packaging for plastic product production to shorten the lead time of projects.

Product Assembly

TONGDA LINK is a “one-stop service” toolmaker that seamlessly integrates components for turnkey solutions throughout the entire product development process.

ONE-STOP SERVICE

With our advanced capabilities, we not only deliver high-quality plastic parts but also provide end-to-end manufacturing services that meet the unique requirements of every project. TONGDA LINK is committed to being a reliable partner for product designers, and OEM manufacturers, offering innovative solutions, superior quality, and exceptional value for product development.

TONGDA LINK Mold is a trusted partner for end-to-end plastic manufacturing solutions. We specialize in high-precision custom mold design and manufacturing, injection molding services, and rapid prototyping, delivering seamless support from concept to mass production. For plastic product designer, TONGDA LINK supports with:

Key Material Selection Factors

-

Part Function: Load-bearing, flexibility, transparency.

-

Environment: Exposure to heat, chemicals, or UV light.

-

Regulatory Compliance: FDA (food contact), UL94 (flammability).

-

Cost: Commodity plastics (PP, PE) vs. engineering-grade (PEEK).

-

Aesthetics: Surface finish, color stability.

Industry Applications by Material

MEDICAL

Plastic material: PC, PEEK, Silicone

(e.g Syringes, surgical tools, implants)

AUTOMOTIVE

Plastic material: PP, ABS, Nylon

(e.g Dashboards, bumpers, connectors)

ELECTRONICS

Plastic material: LCP, PBT, PA

(e.g Connectors, housings, insulators)

CONSUMER GOODS

Plastic material: HDPE, TPE

(e.g Bottles, tool handles, phone cases)