Customizing CNC Machining Parts Production

At TONGDA LINK, we specialize in producing high-quality customized CNC-machined plastic and metal components tailored to meet the specific needs of our customers. Our ISO 9001-certified factory ensures that every product meets strict international quality standards, delivering precision and reliability across industries.

Our Capabilities

We provide CNC machining services for a wide range of applications, including:

- Automotive Industry: High-precision components for critical systems and performance enhancements.

- Aerospace Industry: Lightweight yet durable parts meeting stringent aerospace specifications.

- Industrial Automation: Customized solutions for high-performance machinery and systems.

- Robotics Industry: Precision parts enabling complex movements and operations in robotic systems.

Why Choose TONGDA LINK for CNC Machining?

- Advanced Equipment: Our factory is equipped with 10 CNC machines, including BEIJING JingDiao, Sodick, and MIKRON, ensuring machining precision down to 0.002mm.

- Custom Prototyping: We produce prototypes for design validation and testing, reducing time-to-market for new products.

- Versatile Materials: Expertise in machining both engineering plastics and metals to suit a variety of applications.

- End-to-End Support: From design optimization to production, we provide comprehensive services to meet your project goals.

TONGDA LINK is committed to delivering exceptional quality, innovation, and efficiency. Whether you need prototypes or large-scale production, our CNC machining services ensure precision-crafted components that exceed your expectations.

TONGDA LINK support customers with CNC milling & CNC turning machined components production for prototypes and high-volume production.

TONGDA LINK factory is equipped with two sets of Beijing JingDiao 5 axes CNC machines, which can machining highly precise components to achieve an accuracy of ±5μm.

Comprehensive Solutions

With TONGDA LINK, customers enjoy a seamless production process, from design to delivery:

- Precision Manufacturing: Achieving tolerances as tight as 0.002mm.

- Scalability: Easily transitioning from prototyping to mass production.

- Post-Processing Services: Anodizing, plating, painting, and laser engraving.

- Global Logistics: Efficient and reliable delivery worldwide.

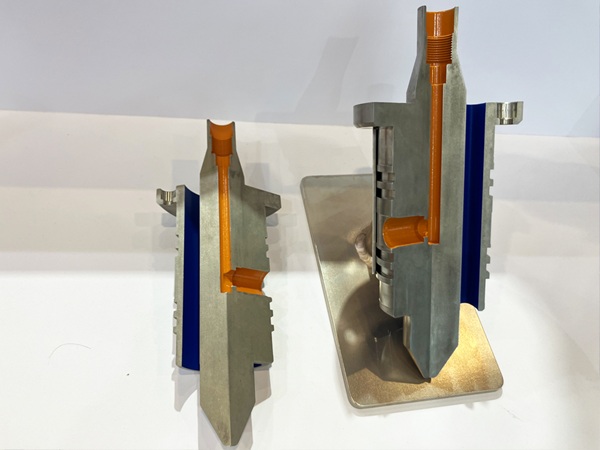

TONGDA LINK's achievements in the oil and gas wells industry

TONGDA LINK’s success in producing and supplying high-tech, science-intensive geophysical equipment, borehole equipment and technologies for studying oil and gas wells.