Gas Assist Injection Molding

Revolutionizing Product Design and Manufacturing Efficiency

Gas Assist Injection Molding 101: Benefits, Process, and TONGDA LINK’s Expert Solutions

In the competitive world of manufacturing, innovation drives efficiency and quality. Gas Assist Injection Molding (GAIM) has emerged as a transformative technology, enabling the production of complex, lightweight, and high-strength parts. As a leader in precision mold manufacturing, TONGDA LINK leverages GAIM to deliver cutting-edge solutions. This article explores the fundamentals and process of gas assisted injection molding, its advantages, challenges, and how TONGDA LINK’s expertise ensures success.

What is Gas Assist Injection Molding?

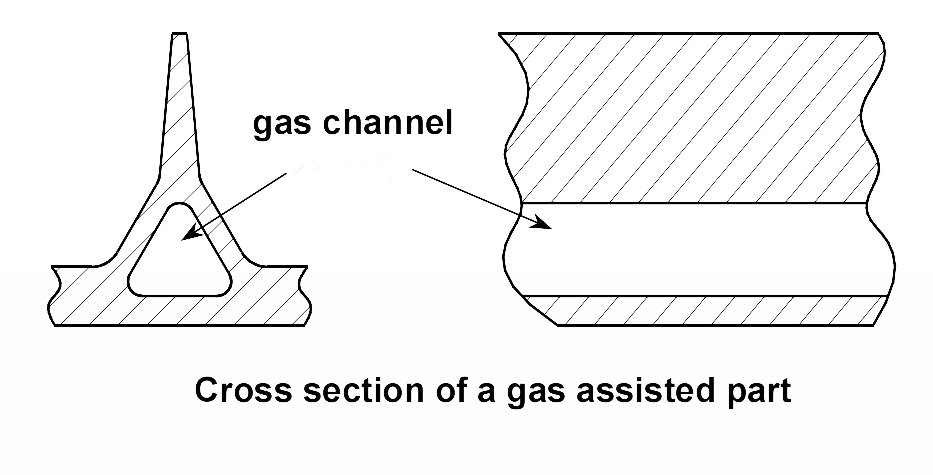

Gas Assist Injection Molding (GAIM) is an advanced plastic molding technique where inert compressed gas (typically nitrogen) is injected into molten plastic to create hollow channels within a part. This process reduces material usage, minimizes sink marks, and enhances structural integrity. The gas displaces the plastic in thick sections, forming uniform walls and optimizing weight distribution—ideal for automotive, consumer goods, and industrial applications.

Why Use Gas Assist Injection Molding?

Gas assisted injection molding offers unique advantages over traditional injection molding:

Lightweighting: Reduces part weight by up to 40% without sacrificing strength.

Cost Efficiency: Lowers material consumption and cycle times.

Design Freedom: Enables complex geometries with fewer weld lines, can have variable nominal wall thickness.

Improved Surface Quality and Aesthetics: Eliminates sink marks and warpage.

Enhanced Durability: Hollow structures improve product stiffness and reduce stress concentrations.

Injection Molding Process: Gas-assisted injection molding can improve polymer flow and reduce clamp tonnage to increase the quality of molded parts.

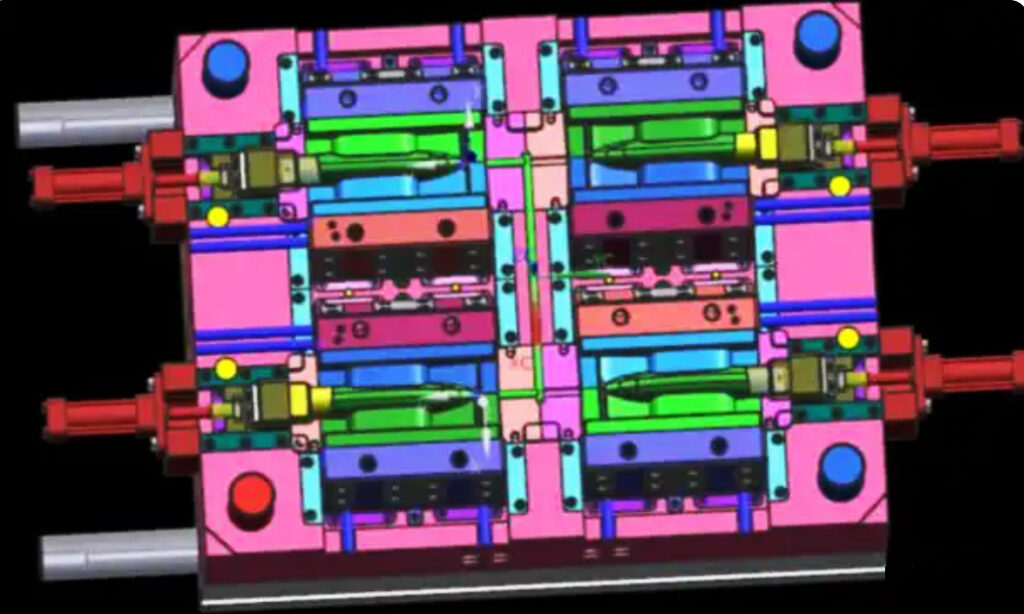

Mold Making: Optimize mold design and structure to extend the mold life time.

Gas-assist injection molding lets you break the rules of conventional injection molding

Comparison of injection molding methods for the large plastic housing of electric machines

| Conventional Injection Molding | Plastic Structural Blowing Injection Moulding | Gas Assisted Injection Molding | |

| Design flexibility | Good | Good | Excellent |

| Product rigidity | Average | Excellent | Good |

| Injection cycle | Good | Poor | Good |

| Product weight | Good | Poor | Excellent |

| Appearance | Good | Average | Good |

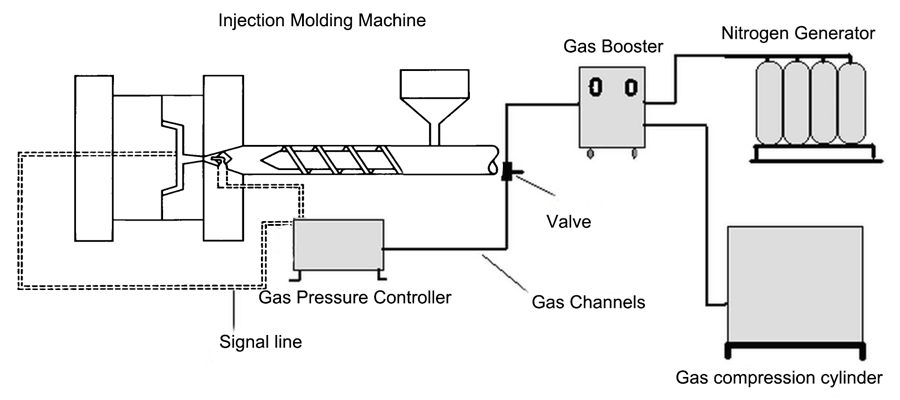

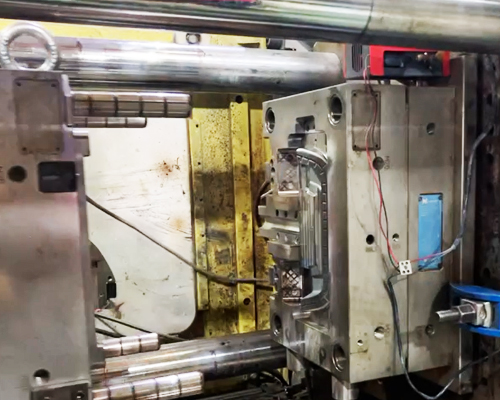

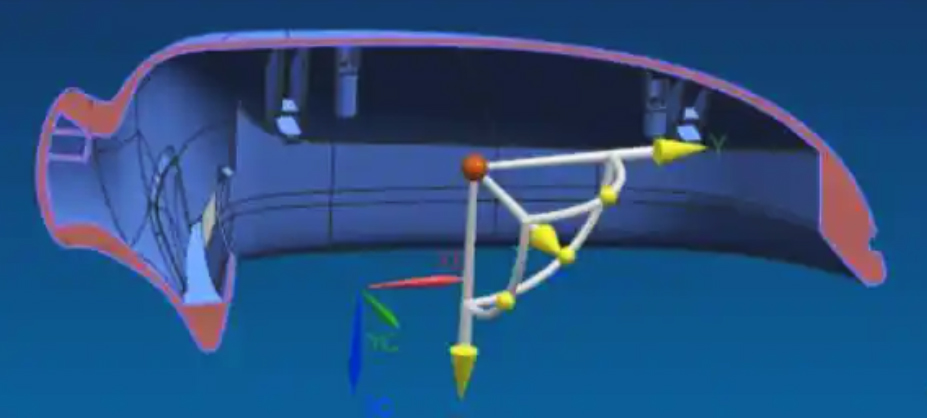

Gas Assist Injection Molding System

Gas Assist Molding System: Key Components

A gas-assist injection molding system integrates specialized equipment:

Gas Injector: Precisely introduces nitrogen into the molten plastic.

Gas Compression Cylinder: Compress nitrogen for injection molding process.

Gas Booster: Increase gas pressure.

Gas Pressure Controller: Manages gas pressure and injection timing.

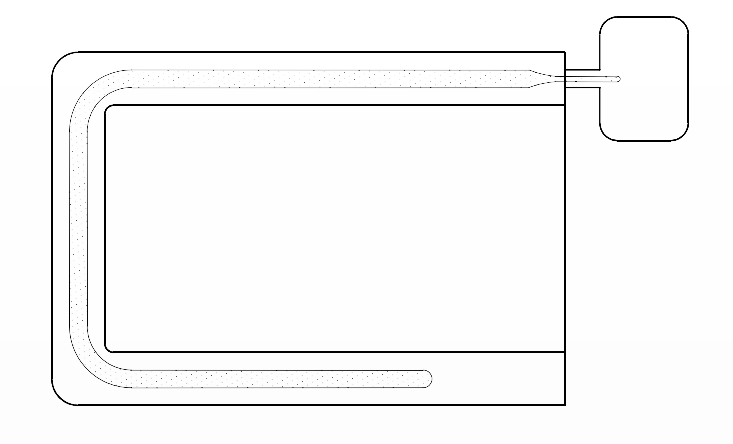

Mold with Gas Channels: Designed to guide gas flow through the part.

Nitrogen Generator: Supplies clean, dry gas to prevent contamination.

What Makes Gas Assisted Molding Challenging? And Solutions?

While gas-assisted injection molding (GAIM) offers significant advantages—such as reduced material use, lower part weight, and minimized sink marks—it demands precise engineering to address inherent complexities. Unlike traditional polymer flow, which can be directly controlled through processing parameters, gas behavior is inherently less predictable. The gas may deviate from expected paths due to its compressibility, interactions with cooling polymer, and mold geometry. Though the underlying physics of gas expansion and displacement is conceptually straightforward, its real-world application requires nuanced understanding to avoid defects. Additionally, mold design becomes more intricate, as engineers must accommodate both polymer and gas flow dynamics without direct control over the latter.

To harness GAIM’s benefits while mitigating risks, the following critical factors must be addressed:

Precision Timing of Gas Injection

Gas introduction must align with the polymer’s cooling phase. Delayed injection risks incomplete cavity filling, while premature injection can disrupt polymer flow or cause blowouts. Synchronizing gas pressure with solidification ensures uniform hollow channels and structural integrity.

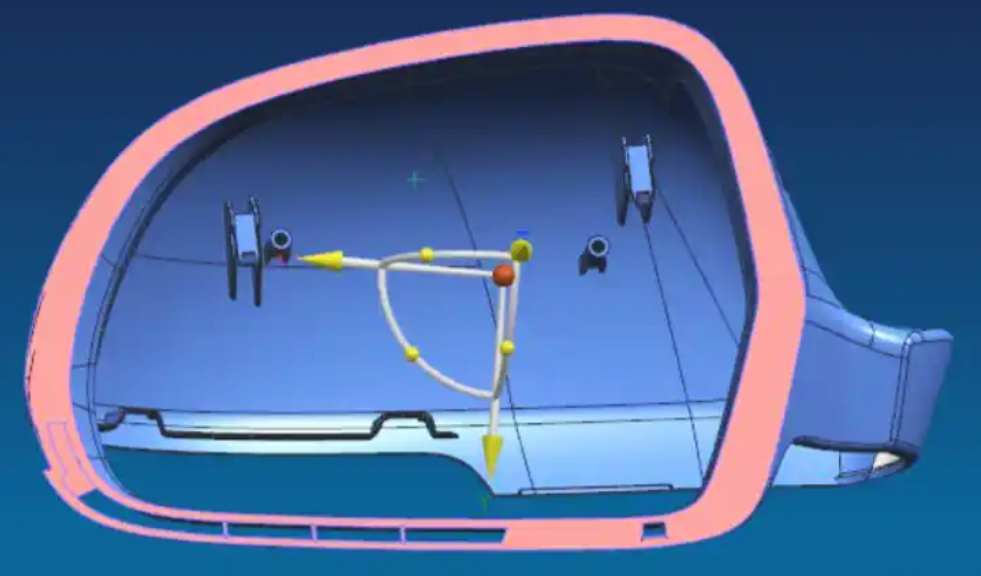

Optimized Gas Channel Design

Gas channels must be strategically positioned to guide expansion and avoid asymmetrical wall thickness, gas trapping, or surface defects (e.g., fingering). Channel geometry, size, and location are tailored to part geometry to balance pressure distribution and material displacement.

Material Compatibility Considerations

Not all polymers are suitable for GAIM. For example, PVC may degrade under high-temperature gas (typically nitrogen), leading to structural weaknesses. Materials must exhibit sufficient melt strength to withstand gas pressure without rupturing.

Integrated Process Optimization

Success hinges on balancing three interdependent variables: polymer injection speed, gas pressure profiles, and cooling rates. Advanced process monitoring (e.g., real-time pressure sensors) and simulation tools are often employed to refine this balance and ensure repeatability.

Ultimately, GAIM requires a paradigm shift from conventional molding: rather than forcing control over the gas, engineers must design molds and processes that leverage gas behavior. By prioritizing these solutions, manufacturers can achieve consistent results while capitalizing on GAIM’s efficiency and design flexibility.

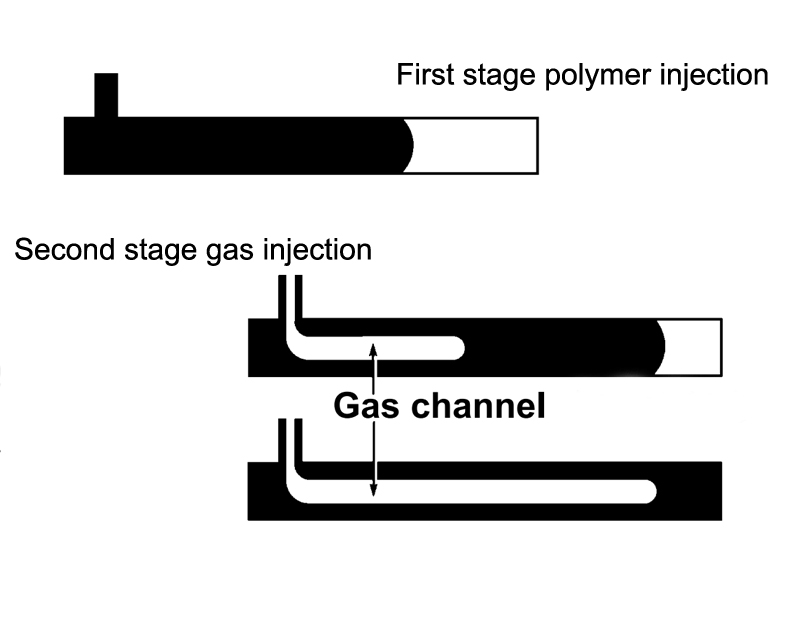

Production Processes in Gas Assisted Injection Molding

The GAIM cycle involves four critical stages:

Plastic Injection: Molten plastic is partially injected into the mold.

Fill the mold cavity with a certain amount of plasticized plastic. The required amount of plastic must be found through experiments to ensure that the gas will not break the surface of the finished product during the nitrogen filling period and that there is an ideal nitrogen filling volume.

Gas Injection: Nitrogen is introduced, displacing plastic to form hollow sections.

Gas can be injected at different times during or after injection. The pressure of gas injection must be greater than the injection pressure to achieve a hollow state of the product.

Gas Packing: Gas pressure holds the plastic against the mold for uniform cooling.

When the interior of the finished product is filled with gas, the pressure of the gas in the hollow part of the finished product becomes the pressure retaining pressure, which can greatly reduce the shrinkage and deformation rate of the finished product.

Gas Venting & Part Ejection: Gas is released, and the finished part is removed.

As the cooling cycle is completed, the gas pressure of the mold drops to atmospheric pressure, and the finished product is ejected from the membrane cavity.

Fundamental Processes in Gas-Assist Injection Molding

Gas-assist injection molding relies on two critical phases:

1,Gas-Assisted Filling Phase

2,Gas-Assisted Packing Phase

1. Gas-Assisted Filling Phase

Key Process Characteristics:

High gas volume utilization (up to 40% of total process volume)

Active melt displacement: Gas directly propels molten material into mold cavities

Process-dependent gas volume requirements:

Filling mode: 40% gas utilization

Packing mode: 5-10% gas utilization

Operational Benefits:

Significant reduction in filling pressure

Elimination of the traditional packing phase

Enhanced shrinkage control

Improved warpage management

60-70% material displacement via gas channels (coring effect)

2. Gas-Assisted Packing Phase

Key Process Characteristics:

Low gas volume requirement (5-10%)

Focused on volumetric compensation for material shrinkage

Distinct functional purpose compared to gas-assisted filling

Critical Differentiators from Filling Phase:

Gas acts as a pressure maintenance tool, not a filling aid

No reduction in baseline filling pressure

The traditional packing phase remains eliminated

Maintains shrinkage and warpage control

Comparative Advantages Across Both Phases:

| Parameter | Filling Phase | Packing Phase |

| Gas Volume | 40% | 5-10% |

| Primary Function | Melt displacement | Shrinkage compensation |

| Pressure Impact | Reduces fill pressure | Maintains pressure |

| Phase Elimination | Packing phase | Packing phase |

| Dimensional Control | Warpage/shrinkage | Warpage/shrinkage |

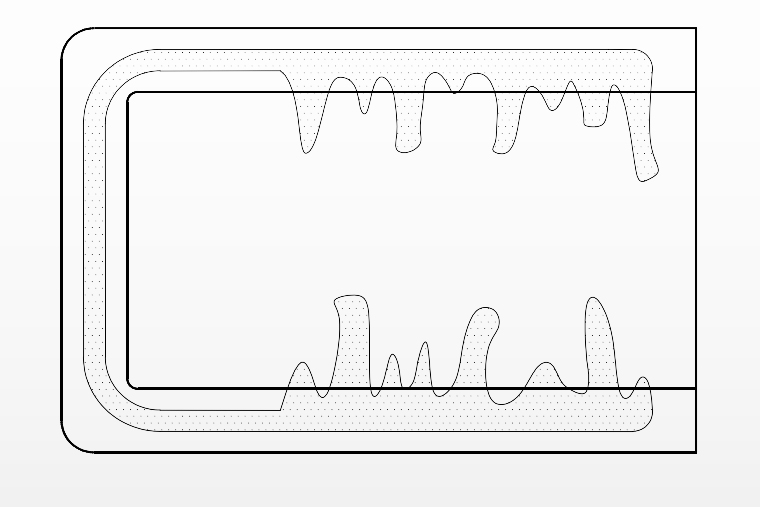

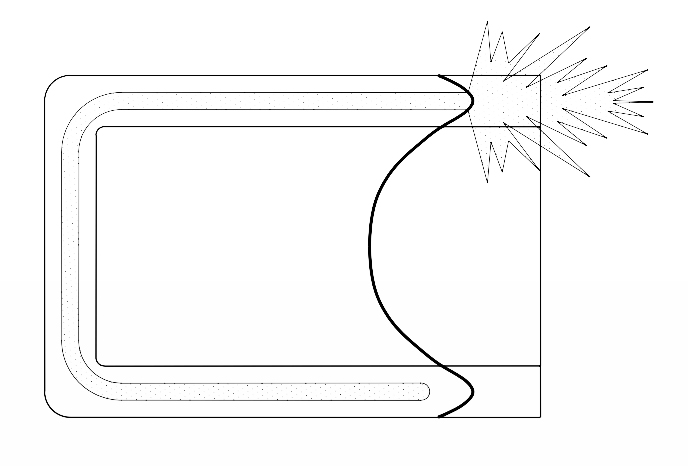

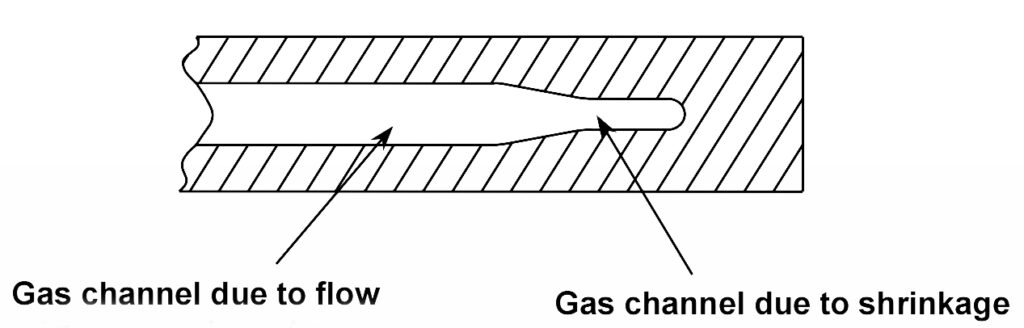

Common Defects During GAIM

Improper execution can lead to:

Gas Blowouts: Gas escaping through weak mold sections.

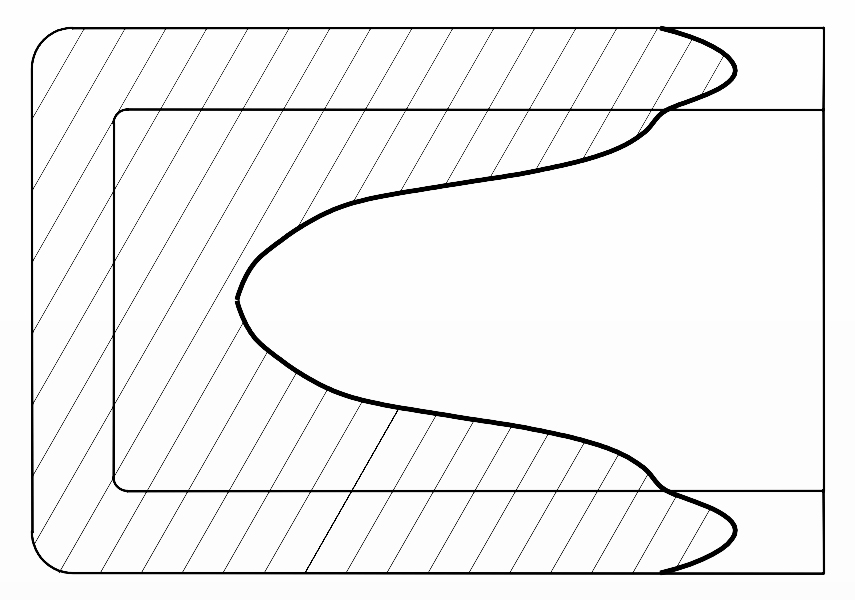

Finger-Like Penetration: Irregular gas channels due to uneven pressure. Undesirable flow of gas into the nominal wall.

Surface Blemishes: Flow marks or marks from gas vents or inconsistent cooling. A hesitation line or witness line on the part as the flow changes from material pushing to gas pushing. These marks make the parts more risky in electroplated parts.

Warpage: Differential shrinkage from uneven wall thickness.

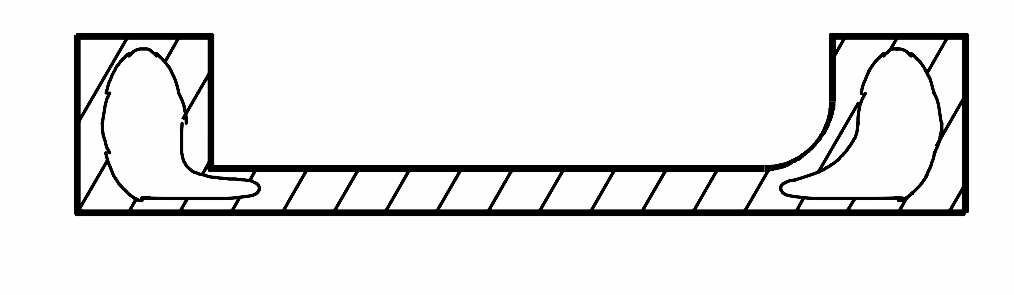

Thick Section: Mismatched plastic filling and gas filling ratios result in thick walls. This will lead to a loss of productivity due to long cooling times. Use of overflows to control gas coring.

Optimizing Cavity Filling in Gas Assist Injection Molding

To minimize defects in gas-assisted injection molding, optimizing cavity filling is critical. The process requires careful consideration of the following factors:

Mold Filling Controls Gas Flow Path

The initial plastic injection phase establishes the gas penetration pattern. Precise control of mold filling ensures predictable gas channel formation and minimizes uneven pressure distribution.

Gas Channels as Strategic Flow Leaders

Gas channels act as flow leaders, directing material distribution to achieve uniform wall thickness. Their design (location, size, and geometry) directly impacts filling efficiency and final part quality.

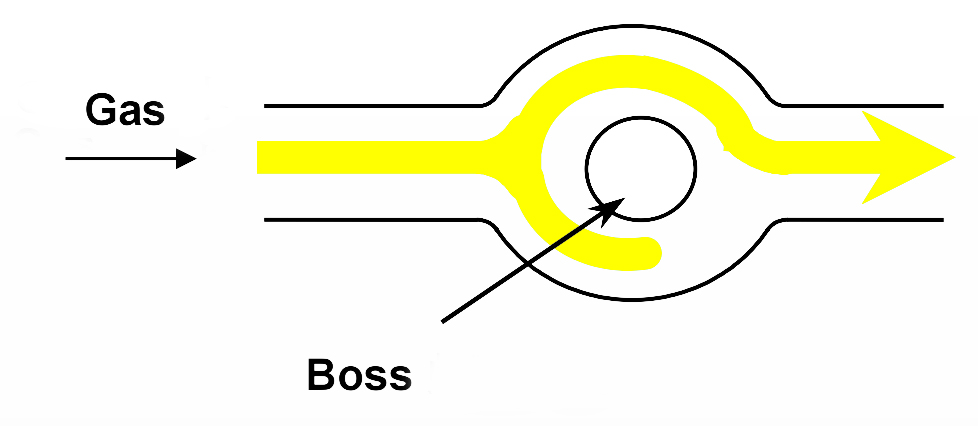

Balancing Flow Leader Size to Avoid Webbing

Oversized flow leaders can cause webbing (unwanted material accumulation between structural features). Optimize channel dimensions to balance flow guidance and webbing prevention.

Symmetry for Consistent Gas Penetration

Symmetrical cavity designs ensure balanced gas pressure and material flow. Asymmetry risks uneven filling, gas entrapment, or part warpage.

Key Takeaway: Successful cavity filling requires a balance between strategic flow leadership (via gas channels) and geometric symmetry. Simulation tools and iterative testing are recommended to validate designs before production.

How to Design The Gas Channel for Gas Assist Injection Molding?

Effective gas channel design requires a deep understanding of gas behavior during injection molding. Below are key physics-based principles and design guidelines to optimize gas penetration and minimize defects:

Physics of Gas Flow

Path of Least Resistance

Gas inherently follows the path of least resistance. By strategically designing gas channels to align with predictable flow behavior, engineers can direct gas penetration as intended.

Pressure Gradient Dominance

Gas flows from high-pressure to low-pressure regions.

The lowest pressure occurs at the molten plastic’s flow front, which gas actively seeks.

Gas will avoid crossing weld lines (where two flow fronts meet), as these regions disrupt pressure gradients.

Temperature-Driven Flow

Gas migrates toward warmer areas due to reduced melt viscosity at higher temperatures.

Elevated melt temperatures lower flow resistance, enabling gas to penetrate thicker sections more effectively.

High melt temperature = Lower melt viscosity

= Less resistance to flow

Volumetric Shrinkage Compensation

Gas pressure replaces the volume lost during plastic cooling and shrinkage.

This ensures consistent packing and minimizes sink marks or voids.

DESIGN GUIDELINES FOR GAS CHANNELS

Flow Direction: Thin-to-Thick Sections

Design gas channels to fill thicker sections last, allowing gas to follow the cooling plastic and compensate for shrinkage.

Gas Injection Placement

Position gas injection points remotely from the flow front at injection initiation. This prevents premature gas breakthrough and ensures uniform cavity filling.

Termination at Ribs

Direct gas flow to terminate at ribs rather than nominal walls.

Ribs act as natural flow barriers, reducing gas entrapment in primary wall sections.

Rib Geometry Optimization

Incorporate radii (fillet transitions) at rib-wall junctions.

Sharp corners risk gas penetration into nominal walls, while radii promote controlled gas containment.

Key Recommendation:

Leverage mold flow simulation software to predict gas penetration paths, validate channel designs, and mitigate risks like webbing or gas entrapment. Iterative testing with prototype molds is critical for refining symmetry and pressure balance.

Part Design for Gas Assisted Injection Mold Manufacturing

Successful GAIM design hinges on:

Uniform Wall Thickness: Prevents gas channel irregularities.

Strategic Gas Channel Placement: Aligns with high-stress areas for optimal strength.

Avoiding Sharp Corners: Reduces stress concentrations and gas turbulence.

Vent Optimization: Ensures clean gas escape without surface defects.

Key Requirements for GAIM

To achieve consistent results:

Material Selection: Use GAIM-compatible resins (e.g., PP, ABS, PC).

High-Precision Molds: Tight tolerances for gas channel accuracy. Mold filling must be balanced, and requires more accurate on the cavity and core.

Advanced Control Systems: Real-time monitoring of pressure and temperature.

Good Injection Molding Machine: Shot metering is very important, and shot size must be consistent. The machine should have a good anti-reverse ring and parallel platens.

Experienced Operators: Skilled technicians to adjust parameters dynamically.

TONGDA LINK’s Expertise in Gas Assist Molding

CONTACT US

At TONGDA LINK, we combine technical mastery with innovation to overcome GAIM challenges:

Customized Solutions: Tailored mold designs for complex geometries.

State-of-the-Art Technology: CNC machining and simulation software for flawless gas channel layouts.

Defect Mitigation: Rigorous testing to eliminate warpage and surface flaws.

End-to-End Support: From material selection to post-production quality checks.

Our proven track record includes delivering high-performance GAIM parts for automotive interiors, appliance housings, and ergonomic tools—showcasing our commitment to precision and efficiency.

Gas Assist Injection Molding is a game-changer for industries demanding lightweight, durable, and cost-effective components. By understanding its intricacies and partnering with experts like TONGDA LINK, manufacturers can unlock unparalleled design possibilities and competitive advantages.

TONGDA LINK – Precision Mold Manufacturing, Engineered for Excellence.

Ready to Innovate?

Contact TONGDA LINK today to explore how our GAIM expertise can elevate your next project.

GET A QUOTE