Video about plastic mold packaging procedure

Video about safe delivery the plastic molds to customers

PLASTIC MOLD PACKAGING & DELIVERY

At TONGDA LINK, we are proud to serve customers worldwide as a leading mold maker in China. We understand that you may have questions about the delivery terms for your plastic molds and the transportation process.

TONGDA LINK supports delivery term: FOB Shenzhen, CIF, DDU, DDP(door to door)

We have three reliable and long-term cooperated logistics freight forwarders. We can support fast and safe delivery at a lower cost than customers do their own.

Transport form: By sea, By air, Express (UPS, DHL, FedEx)

MOLD VALIDATION

All the plastic tools before delivery will be fully inspected according to the checking lists. More details about checking lists, please refer to TONGDA LINK BLOG.

TONGDA LINK helps customers do mold validation if require. Mold validation include:

Installation Qualification;

Operational Qualification;

Performance Qualification.

TONGDA LINK MOLD INSPECTION & CHECKING LIST

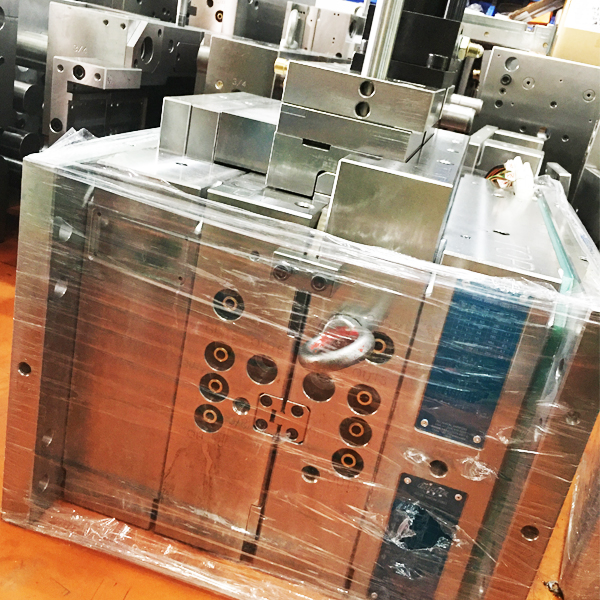

TONGDA LINK plastic mold packaging procedure

TONGDA LINK transports the molds in custom-made wooden boxes without fumigation. Before the mold is packaged, it will be cleaned and tested. The qualified mold will be sprayed with anti-rust oil, then wrapped with film & foam. Then vacuum bagged and finally put into a wooden box.

TONGDA LINK mold quality control and inspection checking list

TONGDA LINK has a strict quality control procedure for plastic mold manufacturing, and the mold project engineer will scrutinize molds according to the checking list before shipping. Click the below arrow to know more details.

LEARN MOREMold waterline testing after assembly

TONGDA LINK will check the waterline by testing to ensure the reassembly after mold cleaning is OK. We will hold the pressure for around 5-8 minutes to record no pressure relief phenomenon or the pressure changing a little to prove that there is no water leakage.

Have you ever encountered mold quality problems–TONGDA LINK solutions

Even with 17 years of mold manufacturing experience, TONGDA LINK always remembers to continuously improve mold manufacturing capabilities, quality requirements, and inspection processes. TONGDA LINK Mold ensures that all plastic molds are high-quality.

TONGDA LINK MOLD–MOLD PACKAGING PROCESS

TONGDA LINK mold is a plastic injection mould manufacturer and injection moulding factory. Equipped with high-precision mold manufacturing equipment for high-quality mold making. This wire EDM can achieve tolerance ± 0.002mm, brand SODICK from Japan.