TONGDA LINK Plastic Mold Manufacturing

TONGDA LINK is a leading mold manufacturer specializing in the production of precision molds and premium-quality injection molded plastic products. Our expertise lies in delivering meticulously crafted solutions that meet the highest industry standards, ensuring durability, accuracy, and exceptional performance for our global clientele.

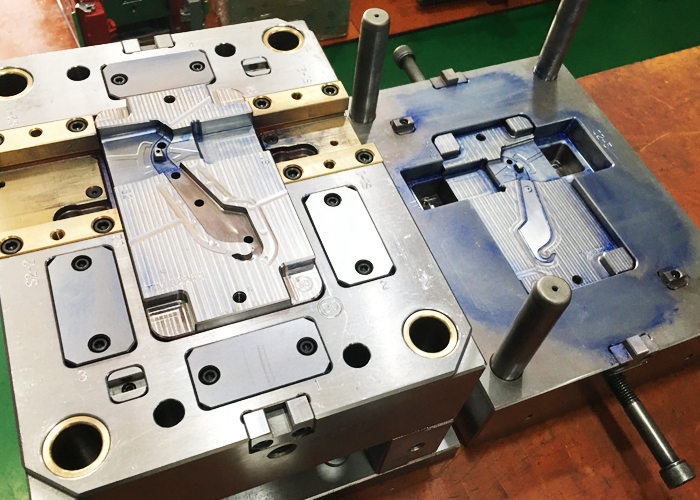

Plastic Injection Mold

Automotive, Medical, Electronics mold projects

Explore injection molding news and industry updates

Find plastic industry news, resources, insight into the plastic injection molding process, and more, on the TONGDA LINK blog:

TONGDA LINK Manufacturing Capabilities

TONGDA LINK support customers with plastic mold manufacturing, Injection Molding, CNC machining, Silicone casting and other. Learn more about our manufacturing capabilities.

Mold with Specification

★The plastic material is PP+EPDM.

★The A & B plate of moldbase is 1.2738H.

★The cavity & core steel is cut from solid A & B plates.

★The slides steel is 1.2344-HRC48-50.

★The Injection system is hot runner to cold runner. There are 8 hot valve nozzles with a sequence injection controller.

★The lead time for T1 is 17 weeks.

★This mold runs on 2800 Ton injection molding machine.

★The plastic material is ASA.

★The mold steel is H13-HRC48-52.

★The steel of A & B plate is P20.

★The slides steel is 2767-HRC54-56.

★The wear plates steel is 2510-HRC56-58.

★There are 4 slides on the fixing(injection) side.

★The Injection system is One hot nozzle to cold runner.

★This mold runs on a 600-ton injection machine.

★The lead time for T1 is 8 weeks.