In the high-stakes world of medical device manufacturing, there is no room for error. From life-sustaining implants to diagnostic tools, every component must meet the most rigorous standards of precision, consistency, and biocompatibility. To meet these demands, the industry relies on two powerful pillars: advanced automation and controlled cleanroom environments.

At TONGDA LINK, as a specialist in precision mold making and CNC machining services, we are at the forefront of integrating these technologies to deliver superior, compliant results for our medical clients.

This blog explores the critical roles of automation and cleanroom production in medical device manufacturing and how they enhance the capabilities of injection molding, CNC machining, and overall supply chain management.

The Non-Negotiable Demands of Medical Device Manufacturing

Before diving into the solutions, it’s essential to understand the unique challenges of the medical sector:

Extreme Precision: Tolerances are often measured in microns. A slight deviation can render a surgical instrument or implant component useless.

Regulatory Compliance: Adherence to standards like ISO 13485 is mandatory, requiring impeccable quality control and full traceability.

Material Expertise: Working with specialized medical-grade plastics (like PEEK, PC, PEI) and metals (like Titanium, Stainless Steel) requires specific knowledge and handling.

Sterility and Biocompatibility: Products must be manufactured in environments that prevent contamination to ensure patient safety.

The Critical Role of Cleanroom Manufacturing

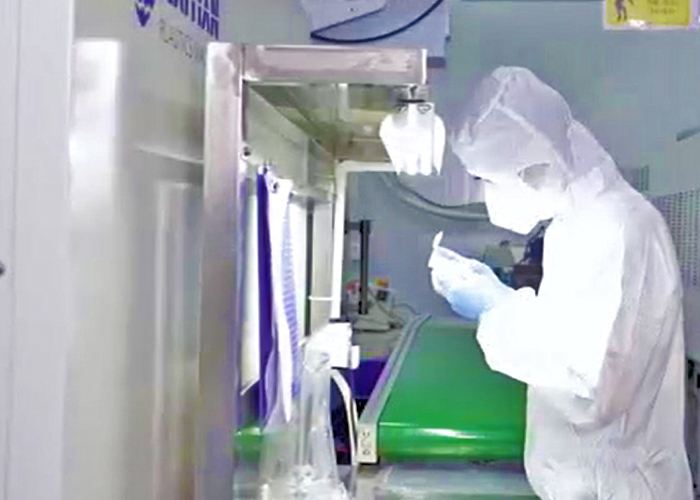

For many medical devices, especially Class II and III devices like implants, drug delivery systems, and surgical tools, standard manufacturing environments aren’t sufficient. Cleanroom production is essential to control particulate and microbial contamination.

Class 100,000 to ISO Class 8 Standards: We operate controlled environments where air quality, temperature, and humidity are strictly regulated. This ensures that injection molded components and machined parts are produced with the highest level of cleanliness from the start.

Cleanroom Molding: Our plastic injection molding cells are often housed within or directly interface with cleanrooms. This is critical for producing items like IV connectors, syringe components, and housing for diagnostic equipment, where even microscopic particles could compromise function or patient health.

Packaging and Assembly: Beyond part production, secondary operations like assembly and packaging can be performed in cleanroom environments to prevent contamination before the device reaches its sterile barrier system

TONGDA LINK is a leading medical device design and mold manufacturing partner, trusted by OEMs from prototyping to cleanroom injection molding production. Help clients to increase speed to market.

Automation in Action: From Mold to Finished Part

Automation is the engine that drives repeatability and efficiency within these controlled environments. It’s about creating a seamless, data-driven workflow.

- Automated Mold Manufacturing (Tooling)

The foundation of any high-quality plastic medical device is the mold tool. Automation here is a game-changer:

High-Speed CNC Machining: Our 5-axis CNC machining centers operate with robotic automation for unattended machining of mold cores and cavities. This ensures complex geometries are produced with unparalleled accuracy and repeatability, 24/7.

Integrated Quality Control: Automated CMM (Coordinate Measuring Machine) probing directly on the CNC machine allows for in-process verification of critical dimensions, ensuring the mold meets exact specifications before it’s used in production.

- Automation in Injection Molding

Once the precision moldis ready, automation takes over in the plastic injection moldingprocess:

Robotic Part Handling & Insert Molding: Collaborative robots (cobots) are used for consistent part extraction, preventing human contact and damage to delicate components. They are also crucial for insert molding and overmolding, where a metal part or a second plastic is introduced into the cycle—a common process for surgical tools and ergonomic handles.

Vision System Integration: Automated vision systems can inspect every part as it is ejected from the mold, checking for flaws like shorts, flashes, or cosmetic defects, and automatically rejecting non-conforming parts. This real-time quality control is invaluable.

Process Monitoring: Automated systems continuously monitor key parameters like pressure, temperature, and cycle time. Any deviation triggers an alert, ensuring every shot is identical. This data log is vital for validation and regulatory compliance.

- Automation in CNC Machining of Medical Components

For metal implants and instruments, CNC machiningis elevated by automation:

Lights-Out Manufacturing: With automated pallet changers and tool magazines, our CNC mills and lathes can run unsupervised for extended periods. This is perfect for producing high volumes of titanium spinal implants or stainless steel surgical staples with guaranteed consistency.

Automated Post-Processing: Integrated systems can handle deburring, polishing, and cleaning in a controlled manner, ensuring that components are ready for sterilization without manual intervention that could introduce contaminants.

The Synergy: Automation Meets Cleanroom Requirements

The combination of automation and cleanroom protocols is particularly powerful. Automation reduces human intervention, which is the largest source of contamination in a cleanroom.

Reduced Human Traffic: Automated guided vehicles (AGVs) and robotics minimize the number of personnel required in the cleanroom, directly lowering the risk of particulate generation.

Consistent Contamination Control: Robots perform the same task the same way every time, without shedding skin particles or varying their procedure, ensuring a consistently clean production process.

Enhanced Traceability: IoT sensors and automated data collection provide a complete digital thread—tracking not only every part’s dimensions but also the environmental conditions (temperature, humidity, particle count) under which it was produced.

The Tangible Benefits for Medical Device OEMs

Integrating automation and cleanroom production delivers clear advantages:

Uncompromising Quality & Compliance: Achieve flawless surface finish, dimensional accuracy, and built-in compliance with FDA and ISO regulations.

Faster Time-to-Market: Accelerate both prototype development and production ramp-up with efficient, repeatable processes.

Improved Cost-Efficiency: Reduce labor costs, minimize scrap, and increase overall equipment effectiveness (OEE), leading to a better total cost of ownership.

Risk Mitigation: The robust validation and traceability inherent in automated, cleanroom processes significantly reduce the risk of product recalls.

TONGDA LINK: Your Partner in Critical Manufacturing

As a trusted mold maker and CNC machining supplier, TONGDA LINK has invested heavily in automation technology and controlled environments. We understand that manufacturing medical devices is a partnership built on trust and technical excellence. Our capabilities in rapid tooling, precision machining, automated production, and cleanroom molding ensure that we can meet your most demanding requirements.

Whether you are in the design for manufacturability phase or ready for full-scale, validated production, our team is ready to provide a competitive quotation and become an extension of your engineering team.