SPI-SPE Mold Standard is a fundamental standard in the plastic injection molding industry. Let’s break down the SPI-SPE Mold Standard in detail.

What is the SPI-SPE Mold Standard?

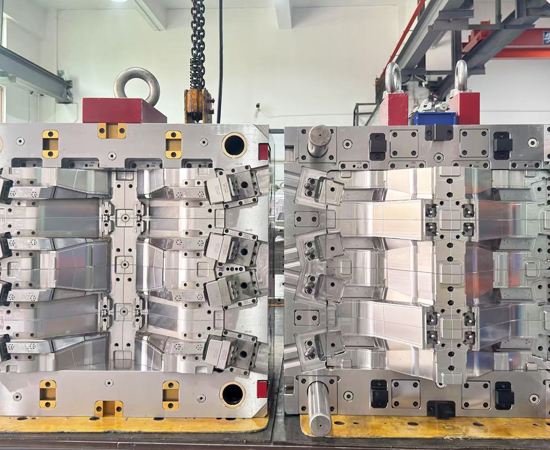

It’s a system designed to classify injection molds based on their construction quality, expected production life, and performance. This provides a common language between mold builders, mold buyers (like product designers and manufacturers), and plastic part producers.

The Core of the Standard: Mold Classifications

The standard defines several classes of molds, typically numbered from 101 through 105. Each class specifies requirements for materials, construction, and durability.

Here is a summary of the most common classifications:

| Mold Class | Expected Production Life | Typical Application | Key Characteristics & Requirements |

| Class 101 | Over 1,000,000 cycles | High-volume production (e.g., automotive, consumer electronics, medical). | Highest Quality. Hardened steel molds. Fully guided (leader pins & bushings on both halves). Extensive cooling channels. High-performance ejection systems. No external welds. For abrasive materials or tight tolerances. |

| Class 102 | Over 500,000 cycles | Medium to high-volume production. | Similar to 101 but may allow for some pre-hardened steels (e.g., P20). Very robust construction, but with a lower lifecycle expectancy. |

| Class 103 | Up to 500,000 cycles | Medium-volume production. | Good Quality. Often uses pre-hardened steels (P20). Requires guided ejection systems. Standard cooling. A common choice for many commercial products. |

| Class 104 | Up to 100,000 cycles | Low-volume production, pilot runs, bridge tools. | Economy Quality. Often uses aluminum or mild steel (e.g., 1040). May have simplified cooling. Not for abrasive materials. Shorter lifespan. |

| Class 105 | Up to 500 cycles | Prototyping, very low-volume runs, R&D. | Prototype Quality. Typically aluminum molds. Minimal cooling. Not designed for long-term production or high-wear materials. Fast and cheap to build. |

Key Parameters Defined by the Standard

The classification dictates specific requirements for various components of the mold:

-

Mold Base:

-

Class 101/102: Requires premium-grade mold bases with hardened and ground plates.

-

Class 103: Requires high-quality commercial mold bases.

-

Class 104/105: Allows for lower-cost, “mill-grade” or aluminum bases.

-

-

Cavity & Core Materials:

-

101: Through-hardened steels (e.g., H13, S7) or high-grade stainless steels.

-

102/103: Pre-hardened steels (e.g., P20) or through-hardened steels.

-

104/105: Aluminum (e.g., 7075-T6), mild steel, or P20.

-

-

Ejection System:

-

101/102: Requires a fully guided ejection system (ejector guide pins and bushings) to prevent wear and binding.

-

103: Requires guide pins on the ejector plate.

-

104/105: Guided ejection is often not required.

-

-

Cooling:

-

101/102: Cooling channels are required in all cavities and core inserts, as well as other critical components. They must be designed for optimal heat transfer.

-

103: Cooling channels are required in cavities and cores.

-

104/105: Cooling may be simplified or omitted in some areas.

-

-

Parting Line Locks:

-

101/102: Required to prevent deflection of the mold halves under high injection pressure.

-

103: Often recommended.

-

104/105: Typically not required.

-

Why is this Standard Important?

- Clear Communication: It eliminates ambiguity. A buyer can specify “a Class 103 mold” and the mold maker knows exactly what is expected in terms of materials and construction.

- Accurate Costing: Higher-class molds cost significantly more to build but last much longer. The standard allows for accurate cost justification based on the required production volume.

- Predictable Performance: It sets expectations for mold longevity, maintenance schedules, and part quality consistency.

- Risk Mitigation: Using the wrong class of mold for a project can lead to catastrophic failure. This standard helps match the tool to the job.