Plastic Injection Molding Tolerance Standards

TONGDA LINK adheres to plastic injection molding tolerance standards as specified in customers’ 2D drawings:

- Germany: DIN 2768

- USA & Mexico: ASME Y14.3M

- Europe: DIN 16742

If no specific requirements are provided, TONGDA LINK applies the Chinese standard GB/T 14486-2008 as the default.

For the automotive industry, the typical plastic injection molding tolerance standards include:

- Automotive Industry Standard: QC-T-29017-1991

- Volkswagen Standard: DIN 16901-1982

- SAIC Standard: MGR ES.22.PL.103 Engineering Drawing Tolerances for Plastic Parts

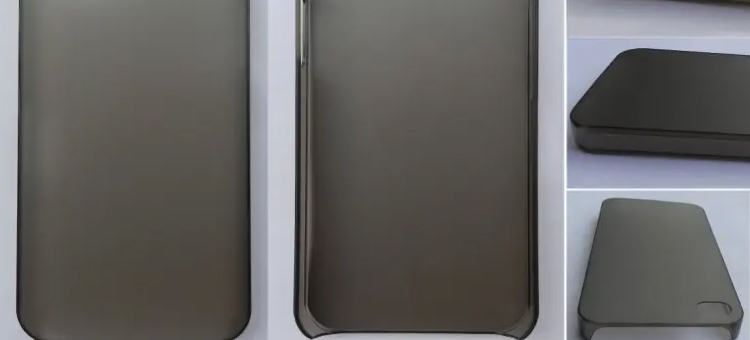

Mold Texture Technology

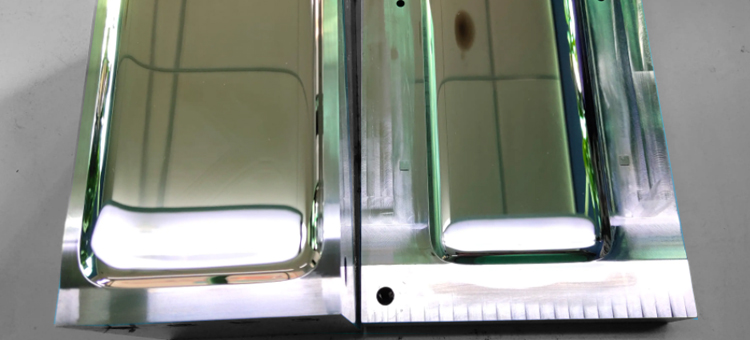

Mold Finish Comparison

The surface polishing of the mold is generally only required to obtain a bright surface. The standard of mirror surface processing is divided into four levels: AO=Ra0.008μm, A1=Ra0.016μm, A3=Ra0.032μm, A4=Ra0.063μm. Mirror finishing places high demands on surface flatness, smoothness and geometric accuracy.

Mold finish comparison chartMold-Tech Texture Drafting Angle Specification

Injection Mold Texturing

Injection molds can be textured using various methods. At TONGDA LINK, we collaborate with YS and MoldTech to ensure the highest quality of plastic mold texturing.

To achieve optimal results, proper draft angles must be incorporated based on the depth of the texture. Failing to account for this may lead to scratches during part ejection.