What is Thin-Walled Injection Molding?

Thin-walled injection molding is an advanced manufacturing process that produces lightweight plastic components with reduced wall thickness, typically less than 1mm. This technique requires specialized molds and high-speed injection molding machines to ensure uniform wall distribution, rapid cooling, and high-strength final products. Thin-wall molding is widely used in industries requiring durable yet lightweight plastic parts, especially in the food packaging sector.

This process requires multi-cavity injection molds, high-speed CNC machining, and advanced mold flow analysis to ensure the highest mold manufacturing standards and superior performance in mass production. To meet the high-speed injection molding demands of thin-walled plastic packaging, mold suppliers must have advanced technical expertise and top-tier injection mold tooling capabilities.

Key requirements for a thin-walled mold manufacturer include:

- High-Precision Mold Design: Every plastic mold manufacturing process must consider mold flow simulation to optimize filling and cooling performance.

- High-Precision Mold Manufacturing: Advanced CNC Machining & EDM process is the base. High-speed CNC machining ensures ultra-precise plastic mold fabrication with tolerances as tight as 0.002mm.

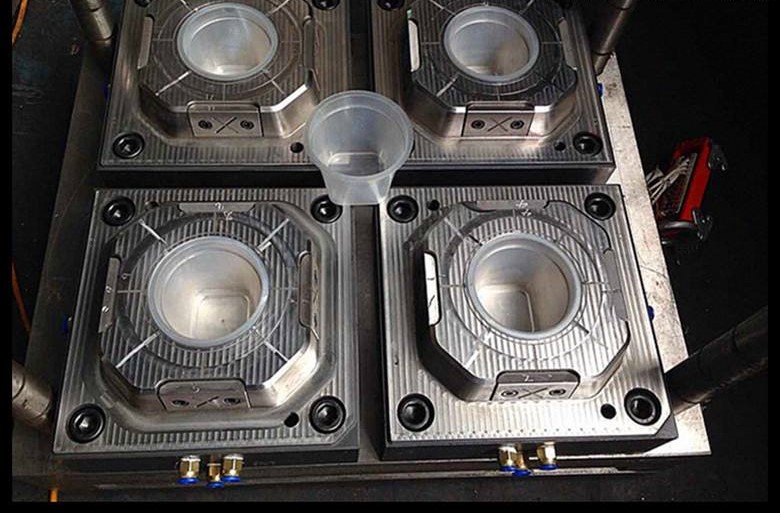

- Multi-Cavity Mold Solutions: 16-cavity and 32-cavity injection molds are crucial for food container injection molding, allowing for higher production efficiency.

- High-Speed Injection Molding Machines: Machines must operate at over 300mm/s injection speed to maintain thin-walled injection molding efficiency.

- Optimized Cooling Systems: Precision mold design must incorporate advanced cooling channels for rapid cycle times in plastic packaging injection molding.

- Durable Mold Steel: Using H13, S136, and 420 stainless steel ensures long-lasting injection mold tooling with minimal wear.

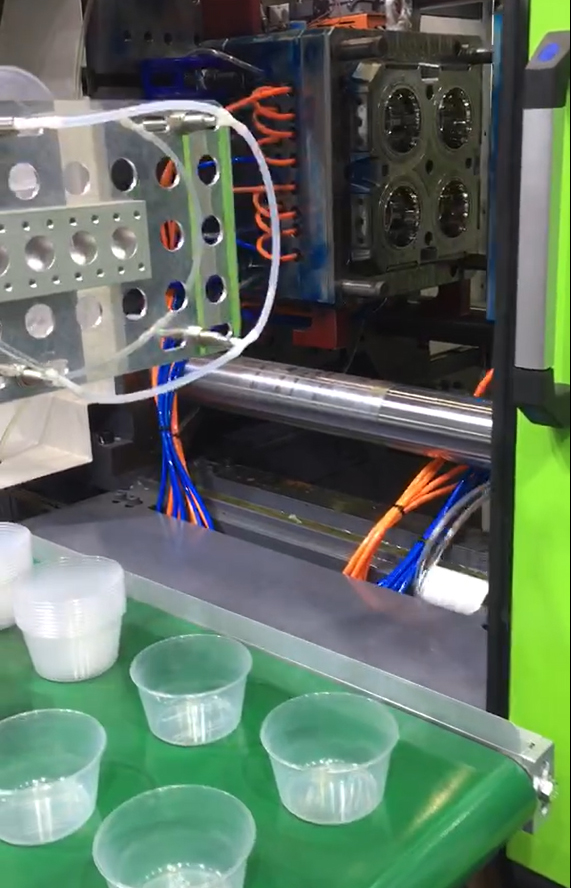

- Automated Production & Robotics: Robotics and fully automatic injection molding systems enhance productivity and consistency.

- Expertise in Hot Runner Systems: Reducing material waste and improving part consistency.

- Strict Quality Control Systems: Cleanroom injection molding processes must comply with food-grade plastic injection molding standards for hygiene and safety.

Thin-Walled Injection Molding Applications in Packaging

Thin-walled plastic packaging injection molding is widely used in the food industry due to its lightweight, cost-effective, and durable properties. The demand for disposable food containers, disposable lunch boxes, takeaway lunch boxes, food storage boxes continues to grow, driven by the rising popularity of takeout, meal delivery services, and microwaveable packaging. Thin-walled injection molding is a cornerstone of the food packaging industry.

It enables the production of:

- Disposable Food Containers: Lightweight, stackable, and cost-effective solutions for takeout and food delivery services.

- Lids and Covers: Airtight and secure sealing solutions for various food products.

- Dairy Product Packaging: Yogurt cups and butter tubs that require high durability.

- Microwaveable Containers: Heat-resistant plastic packaging for convenience meals.

Global Market Data on Thin-Walled Food Containers

The demand for thin-walled food containers, such as disposable food containers, disposable lunch boxes, takeaway lunch boxes, food storage boxes has surged due to the increase in takeout and delivery services. According to industry reports:

- The global market for thin-walled plastic packaging is projected to grow at a CAGR of 6.5% from 2024 to 2030.

- Asia-Pacific leads in production and consumption, with China being the largest producer of thin-walled food packaging solutions.

- Over 60% of food packaging demand is driven by fast food and convenience meal consumption.

- The surge in e-commerce meal delivery and quick-service restaurants (QSRs) fuels the demand for thin-walled food container injection molding.

Key Capabilities of TONGDA LINK MOLD:

As a leading thin-walled mold manufacturer in China, TONGDA LINK specializes in precision mold design, multi-cavity mold production, and high-speed injection molding for food packaging solutions. Produce disposable food containers, disposable lunch boxes, takeaway lunch boxes, food storage boxes for huge market demand.

- Custom Thin-Walled Mold Design: Tailored solutions to meet different food container specifications.

- High-Precision Mold Making: With 10 advanced CNC machining centers, the High-Speed CNC Machining ensuring precise cavity and core fabrication for rapid cycle production. TONGDA LINK ensures that every plastic mold manufacturing project achieves the highest precision injection molding standards.

- Multi-Cavity Mold Production: We develop 16-cavity and 32-cavity molds to support high-volume food-grade plastic injection molding.

- Hot Runner System Integration: Reducing waste and improving part consistency.

- Optimized Cooling and Venting Systems: Using mold flow simulation, we improve cooling efficiency to reduce cycle times to as low as 3-5 seconds.

- Injection Mold Tooling Durability: All molds are made from premium-grade mold steel (H13, S136, and 420 stainless steel) to ensure a long lifespan.

- Automated Quality Control: Every mold undergoes DFM analysis, mold validation trials, and high-speed vision inspection to ensure defect-free production.

- Mold Maintenance and Spare Parts Supply: Providing long-term support for production sustainability.

TONGDA LINK’s Thin-Walled Food Container Production:

- Cleanroom Injection Molding: Our factory features a certified cleanroom production area, ensuring hygienic and food-safe plastic packaging.

- 24/7 Fully Automatic Production: Utilizing robotic automation and conveyor systems, we achieve continuous high-speed injection molding.

- High-Speed Injection Machines: Our precision injection molding machines operate at over 300mm/s, producing thin-walled plastic packaging at unmatched efficiency.

- Large-Scale Inventory for Wholesalers: We maintain a substantial stock of food containers, ensuring fast delivery for bulk orders.

- Strict Quality Control: Conducting rigorous inspections to ensure all products meet FDA and EU food safety standards.

Our advantages include:

- ISO-Certified Manufacturing: We meet global standards for food-grade plastic injection molding.

- Sustainable Manufacturing Practices: We support biodegradable and recyclable plastic materials.

- Rapid Lead Times: Our streamlined production process ensures fast mold delivery and high-volume injection molding.

- Global Logistics & Customer Support: We supply plastic injection molds and finished products to clients worldwide.