Plastic injection molding is a cornerstone of modern manufacturing, producing everything from medical devices to automotive parts and the smartphone case in your hand. It’s a marvel of efficiency and repeatability. However, a single oversight can lead to defective parts, costly downtime, or even damage to expensive machinery.

Whether you’re an engineer, a product designer, or a project manager, understanding the key precautions in the injection molding process is critical for success. This guide will walk you through the essential safeguards to take at every stage, from design to delivery.

The Pre-Production Phase: An Ounce of Prevention

The most crucial precautions happen before a single pellet of plastic is melted.

Precaution: Don’t Rush the Design for Manufacturability (DFM) Analysis.

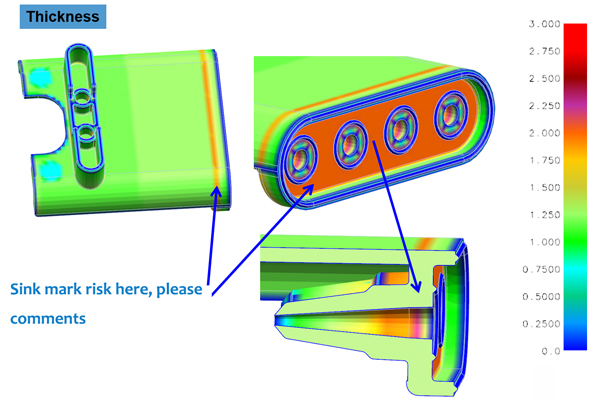

Why: A perfect CAD model does not always translate into a manufacturable part. Issues like wall thickness, sharp corners, and undercuts can cause major problems.

Action: Work closely with your molding partner during the DFM stage. They will analyze your design and suggest critical changes—like adding draft angles for easier ejection, specifying appropriate wall thickness to avoid sinks and warpage, and recommending radii on sharp corners to reduce stress concentration and improve material flow.

Contact TONGDA LINK Today For An Expert DFM Analysis and Quote

Precaution: Never Underestimate Material Selection and Drying.

Why: Different plastics have vastly different properties (strength, flexibility, heat resistance, etc.). Using the wrong material is a recipe for failure. Furthermore, hygroscopic resins (like Nylon, PET, PC) absorb moisture from the air.

Action: Select the material based on the part’s functional and environmental requirements. For hygroscopic materials, pre-dry them strictly according to the manufacturer’s specifications (usually 2-4 hours at 160-180°F / 70-80°C). Using wet material causes surface defects like splay (silver streaks) and significantly degrades mechanical properties.

Precaution: Avoid Material Mix-Ups and Contamination at All Costs.

Why: Introducing a different plastic or even a different color into the hopper can ruin an entire production run. Contaminated material can lead to part failure, clogged filters, and un-melted particles, causing surface defects and weak structural integrity.

Action: Implement a strict material handling protocol:

Clear Labeling: All material containers and hoppers must be clearly labeled with the material type and grade.

Dedicated Equipment: Use dedicated loading equipment (e.g., vacuum loaders, hoppers) for different materials or colors to prevent cross-contamination.

Purge Thoroughly: When changing materials, perform a complete and thorough purge of the injection unit using an appropriate purge compound.

“First-In, First-Out” (FIFO): Use older material stocks first to prevent degradation from prolonged storage.

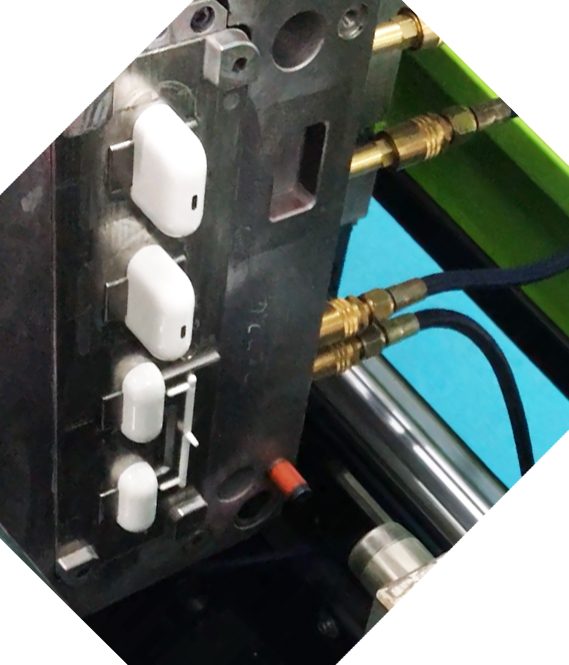

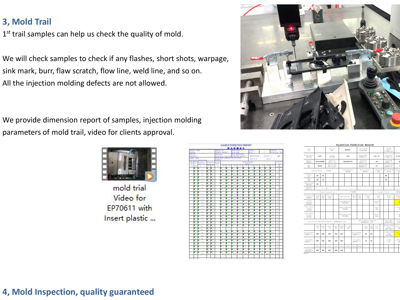

Precaution: Thoroughly Validate the Mold Tool.

Why: The plastic mold is the most expensive part of the injection molding production process. A flaw in the mold can be catastrophic.

Action: Before full production, conduct a Trial Run (or T1 Sample). This run tests the mold in a real machine, allowing you to check for:

Part Function: Does it fit and work as intended?

Dimensional Accuracy: Does it meet all specified tolerances?

Aesthetic Quality: Is the surface finish acceptable?

Ejection: Does the part eject cleanly without sticking or damage?

The Production Phase: Vigilance on the Floor

Once production begins, consistent monitoring is key to maintaining quality.

Precaution: Monitor and Control Machine Parameters Relentlessly.

Why: Injection molding is a process of high heat and pressure. Inconsistent settings lead to inconsistent parts.

Action: The key parameters to monitor and document are:

Temperature: Nozzle, barrel, and mold temperatures must be stable.

Injection Pressure and Speed: These affect how the material fills the cavity and can impact part strength and appearance.

Cooling Time: Insufficient cooling causes parts to deform upon ejection; Too much cooling reduces efficiency.

Back Pressure: Important for achieving a homogeneous melt.

Precaution: Take Extra Precautions for Transparent Parts.

Why: Any flaw, no matter how small, is instantly visible in a transparent component. Achieving optical clarity requires exceptional attention to detail.

Action:

Mold Polish: The mold must have a high-quality polish, often to a #A1 or diamond-grade finish, as any tooling mark will be replicated onto the part.

Gate Design: Gate location and type are critical. Pin-point gates are often preferred to minimize visual vestiges.

Process Settings: Use higher injection speeds to prevent flow lines and ensure a homogeneous melt. Packing pressure must be optimized to avoid stress whitening or internal stresses that can cause birefringence (optical distortion).

Strict Contamination Control: As mentioned above, even a single speck of a different colored material can ruin a transparent part.

Let Our Expertise Be Your Advantage

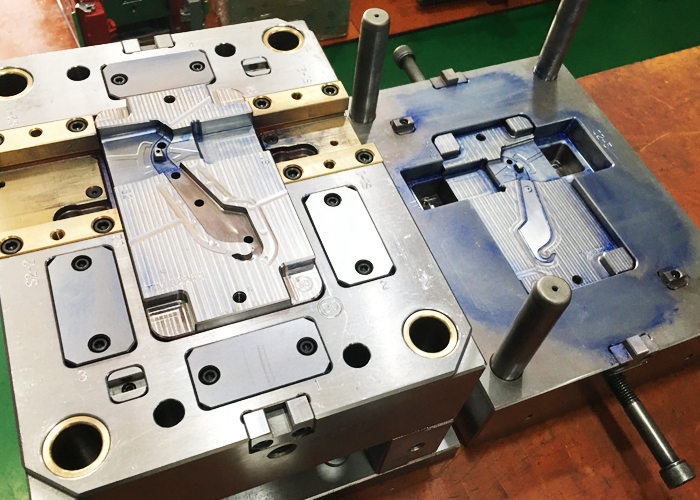

Precaution: Implement a Strict Mold Maintenance Schedule.

Why: Molds are subject to wear and tear, corrosion, and damage. A poorly maintained mold will produce defective parts and can break down completely.

Action: Establish a regular maintenance routine. This includes:

Cleaning: Removing plastic residues, rust, and coatings.

Lubrication: Ensuring ejector pins, sliders, and other moving parts operate smoothly.

Inspection: Checking for damage, wear, and corrosion on critical surfaces.

Precaution: Prioritize Operator Safety.

Why: Injection molding machines operate with extreme force and high temperatures.

Action: Enforce strict safety protocols:

Machine Guards: Never operate a machine with safety guards interlocked or removed.

Lockout/Tagout (LOTO): Follow LOTO procedures religiously during any mold change or maintenance to prevent accidental machine activation.

Personal Protective Equipment (PPE): Heat-resistant gloves, safety glasses, and closed-toe shoes are mandatory.

The Post-Production Phase: Ensuring Consistency

The job isn’t over once the parts are out of the mold.

Precaution: Establish a Robust Quality Control (QC) Process.

Why: Catching a defect early saves time and money. You can’t inspect quality into a part; you must build it into the process.

Action: Use a combination of techniques:

First-Article Inspection: A thorough inspection of the first parts from a production run.

In-Process Checks: Operator visually checks parts periodically for obvious defects like short shots, burns, or flash.

Statistical Process Control (SPC): Monitoring key dimensions statistically to identify trends before they become defects.

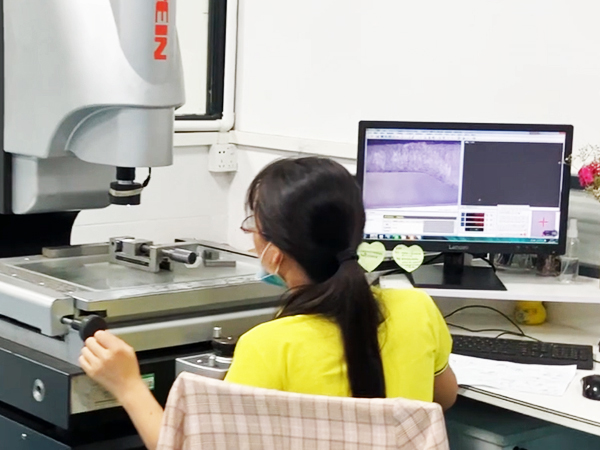

Coordinate Measuring Machine (CMM): For high-precision parts, use a CMM for accurate dimensional validation.

Precaution: Handle and Package Parts Correctly.

Why: Parts can be scratched, deformed, or contaminated after ejection.

Action: Use appropriate containers, separators, and packaging to protect parts, especially those with critical cosmetic surfaces. For some materials, controlling the storage environment (temperature, humidity) is also important.

Common Defects to Be Precautious Of:

Being able to identify a problem is the first step to solving it. Keep an eye out for:

Short Shot: Incomplete filling of the mold cavity. Often caused by low injection speed/pressure, insufficient material, or blocked gates.

Sink Marks: Small craters on thick sections. Caused by inadequate cooling or packing pressure.

Warping: Twisting or bending of the part. Caused by uneven cooling or internal stresses.

Flash: Thin layer of excess plastic on the part edge. Caused by excessive injection pressure or a damaged/ill-fitted mold.

Partnering with an Expert: TONGDA LINK’s Advantages

Navigating these precautions alone can be daunting. This is where partnering with an experienced manufacturer like TONGDA LINK becomes a critical advantage. We mitigate these risks through our core strengths:

Expert DFM Analysis: Our engineering team provides in-depth DFM feedback early in the process, identifying potential issues with material selection, wall thickness, gating, and ejection to ensure your design is optimized for manufacture.

State-of-the-Art Facility & Process Control: We maintain a controlled manufacturing environment with modern machinery equipped with precise process monitoring. This ensures consistency, repeatability, and strict adherence to the parameters required for challenging projects like transparent parts.

Rigorous Quality Management System: From incoming material inspection (preventing material mix-ups) to in-process SPC and final CMM verification, our integrated QC system is designed to catch deviations early, guaranteeing that every part that leaves our facility meets your exact specifications.

Proactive Maintenance & Expertise: Our molds are managed under a proactive maintenance schedule, and our technicians are trained to the highest standards in both operation and safety protocols, ensuring longevity for your tooling and reliability for your production schedules.

Precision Through Process

The plastic injection molding process is a symphony of precise variables working in harmony. The single most important precaution is to work with an experienced and communicative manufacturing partner. A good partner will guide you through DFM, maintain rigorous processes, and have a robust QC system in place to mitigate risks at every turn.

By respecting these precautions—from meticulous design to disciplined production—you can leverage the full power of injection molding to produce high-quality, reliable, and cost-effective plastic parts, batch after batch.