TONGDA LINK: Your Trusted Plastic Injection Mold Manufacturer

Learn moreStay Ahead in the Mold Industry: Cutting-Edge Trends, Expert Analysis, and Solutions Crafted for Your Success.

Explore the TONGDA LINK Blog — Where Precision Meets Innovation.

ALL BLOGS

Gas Assist Injection Molding 101: Benefits, Process, and TONGDA LINK’s Expert Solutions

In the competitive world of manufacturing, innovation drives efficiency and quality. Gas Assist Injection Molding (GAIM) has emerged as a transformative technology, enabling the production of complex, lightweight, and high-strength parts.

Enhancing Product Design with Insert Molding and Overmolding: A Complete Guide

Enter insert molding and overmolding—two advanced manufacturing techniques that redefine what’s possible in product design. To solve the industries push for lighter, stronger, and more integrated component for multi-material manufacturing.

General Applications of Commonly Used Thermoplastic in Injection Molding

Injection molding is one of the most versatile and widely used manufacturing processes, producing everything from tiny components to large industrial parts. Selecting the right plastic material is crucial to achieving optimal performance, cost-efficiency, and durability.

Guide to Selecting Thermoplastic Materials for Plastic Molded Products

For plastic product designers, a comprehensive understanding of the properties and applications of commodity plastics, engineering plastics, and medical plastics is essential.

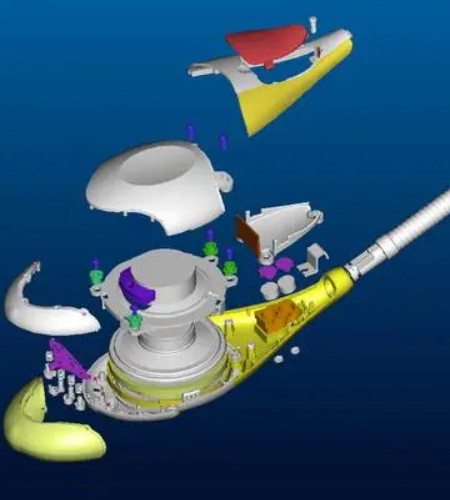

How to Make Product Development from Concept to Reality?

Mold makers play a pivotal role in transforming abstract concepts into tangible, market-ready products. For product developers, OEM manufacturers, and product designers, partnering with a skilled mold maker ensures…

What Are The Precautions For The Plastic Injection Molding Production Process?

Plastic injection molding is a cornerstone of modern manufacturing, producing everything from medical devices to automotive parts and the smartphone case in your hand.

Precision & Progress: How Automation and Cleanroom Manufacturing Elevate Medical Devices

In the high-stakes world of medical device manufacturing, there is no room for error. From life-sustaining implants to diagnostic tools, every component must meet …

Troubleshooting 101: Common Injection Molding Problems and How to Fix Them

Injection molding is a necessity of modern manufacturing. It’s fast, efficient, and produces incredibly consistent, high-quality parts. But let’s be honest: even for seasoned professionals, the process can sometimes be difficult …

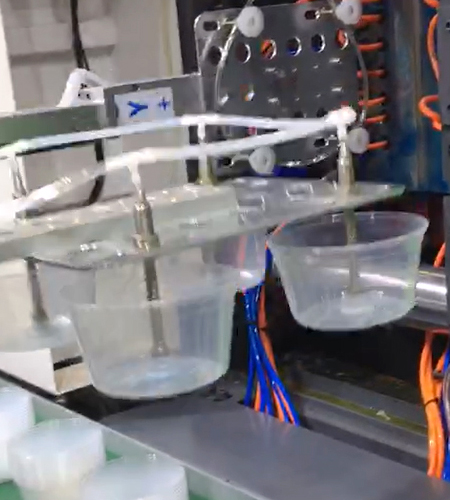

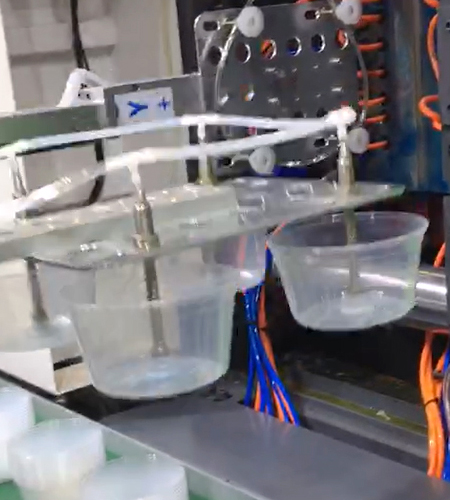

Thin-Walled Injection Molding: Precision, Efficiency, and High-Volume Food Container Production

Thin-walled injection molding is an advanced manufacturing process that produces lightweight plastic components with reduced wall thickness, typically less than 1mm. This technique requires…

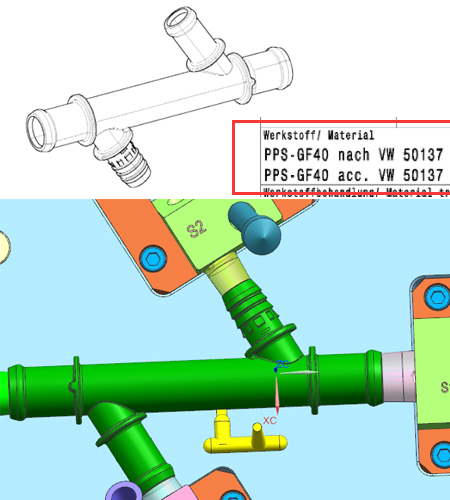

Mastering PPS Plastic: Properties, Injection Molding Processing & Applications

(With Focus on Glass Fiber-Reinforced Composites) Polyphenylene Sulfide (PPS) stands out as a high-performance engineering thermoplastic, offering…

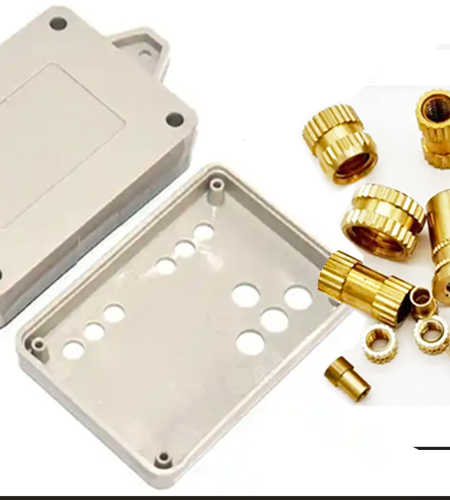

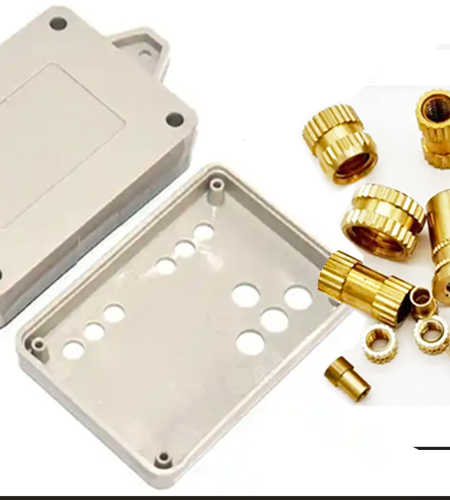

How to Make Metal Inserts Into Plastic Parts?

Metal insert integration enhances plastic parts by providing greater strength, wear resistance, electrical conductivity, and durable threaded connections – benefits often essential for demanding applications. TONGDA LINK, a leader in plastic manufacturing, …

The Critical Role of Silicone Casting and Prototyping in Plastic Product Development

In the dynamic world of product development, prototyping isn’t just a step—it’s the cornerstone of innovation. But what exactly is prototyping? It’s the process of turning abstract ideas into functional models…

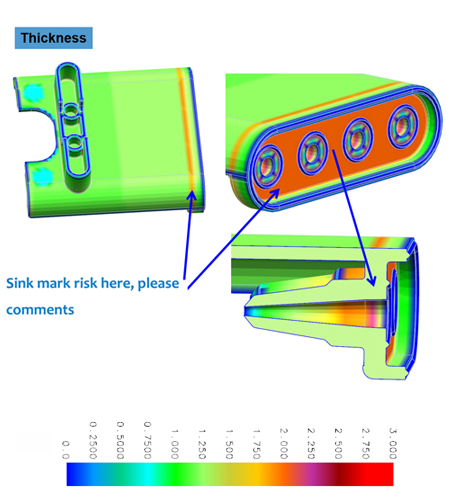

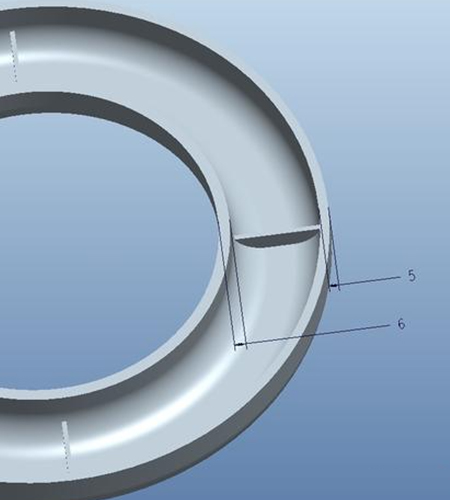

Injection Molding: Wall Thickness Design Principles Achieving Uniform Wall Thickness

Uniform wall thickness is a foundational principle in designing plastic injection-molded parts, essential for avoiding defects like sink marks, warpage, short shots, and part failure.

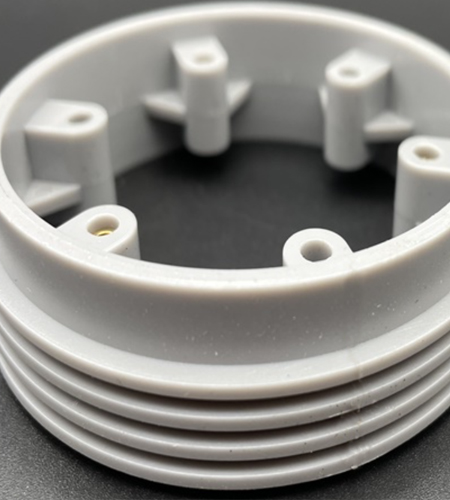

Mastering Product Design Details: Screw Bosses, Seams, Snap-Fits & More Feature

Designing great products hinges on nailing the smallest details. After all, it’s screw bosses, seams, and snap-fits that determine whether a device rattles, cracks, or withstands daily abuse.

Thin-Walled Injection Molding: Precision, Efficiency, and High-Volume Food Container Production

Thin-walled injection molding is an advanced manufacturing process that produces lightweight plastic components with reduced wall thickness, typically less than 1mm. This technique requires…

Plastic Gears: Technological Wisdom In Lightweight Transmission

In the field of mechanical transmission, gears, as core components for transmitting power and motion, have long garnered significant attention. Plastic gears …

How to Make Metal Inserts Into Plastic Parts?

Metal insert integration enhances plastic parts by providing greater strength, wear resistance, electrical conductivity, and durable threaded connections – benefits often essential for demanding applications. TONGDA LINK, a leader in plastic manufacturing, …

The Critical Role of Silicone Casting and Prototyping in Plastic Product Development

In the dynamic world of product development, prototyping isn’t just a step—it’s the cornerstone of innovation. But what exactly is prototyping? It’s the process of turning abstract ideas into functional models…