Rapid Prototyping

Rapid prototyping is a critical step in the development and manufacturing of new plastic products. At TONGDA LINK MOLD, we utilize advanced techniques, including silicone casting, to validate and optimize product designs early in the process. This ensures compatibility with plastic injection molding and prepares products for high-volume mass production.

Skipping the prototyping phase can lead to costly errors. Even minor design flaws may result in defective molds, production delays, or product failures, significantly increasing costs. By incorporating rapid prototyping, including silicone casting, TONGDA LINK MOLD helps clients minimize these risks. This approach allows for iterative design improvements, performance testing, and functional validation, ensuring higher-quality products and streamlined manufacturing workflows.

Would you like to explore how silicone casting fits into the prototyping process or learn more about TONGDA LINK MOLD’s capabilities?

Rapid prototyping is a crucial part of new plastic product development, and TONGDA LINK MOLD excels in providing tailored solutions for OEM customers and product design and development clients. We offer a variety of prototyping options, including:

- CNC-machined plastic and metal prototypes for precise and durable models.

- Silicone casted prototypes to replicate parts quickly and efficiently.

- 3D-printed prototypes using additive manufacturing for rapid design iteration and validation.

These prototyping methods ensure that product designs are optimized for plastic injection molding and ready for high-volume mass production. By leveraging rapid prototyping, TONGDA LINK MOLD helps clients identify and resolve design issues early, minimizing costs and improving product quality. Would you like details on any specific prototyping method or how it integrates with your project?

Engineering Support for Seamless Production

TONGDA LINK is the supplier for the prototype production, goes beyond mold making. We provide end-to-end support:

Prototype-to-Production Workflow: From silicone casting to full-scale injection molding.

Material Selection Guidance: Match polymers to mechanical, thermal, or regulatory needs.

Low-Volume Production: Ideal for niche markets or pilot runs.

Quality Assurance: ISO-certified processes with rigorous inspection protocols.

TONGDA LINK MOLD supports rapid prototyping for coffee maker, vacuum cleaner, massager, microphone, game device, steam ironing machine, etc.

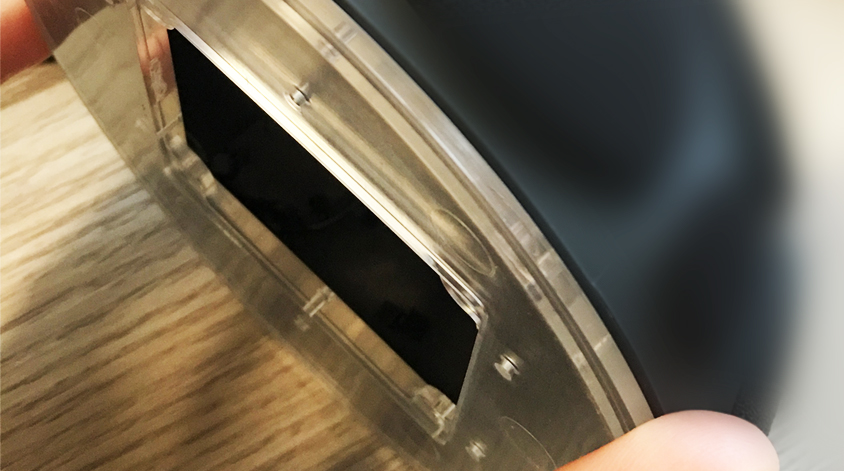

Rapid prototyping process is various. Prototypes can be made by silicone casting, vacuum casting molding, CNC machining, 3D printing (additive manufacturing), etc. TONGDA LINK MOLD chooses prototyping technology depend on product feature and quantity.

The accompanying video explains CNC machining. CNC machining plays a critical role in rapid prototyping and efficiency in producing high-precision, functional metal components with speed and reliability.

Prototypes are primarily used to validate a product’s appearance, structural design, and market viability through rapid testing. For metal components, rapid prototyping typically employs methods like CNC machining and additive manufacturing.

-

CNC Machining: Delivers high-precision prototypes that not only verify form and structure but also meet functional performance requirements, making them suitable for rigorous mechanical or operational testing.

-

Additive Manufacturing (3D Printing): Often prioritized for engineering validation and marketing purposes, such as assessing design ergonomics, gathering user feedback, or showcasing concepts to stakeholders.