The Critical Role of Mold Maker Elevate Product Development from Concept to Reality

In today’s fast-paced manufacturing landscape, bringing innovative products to market requires more than just visionary ideas—it demands precision, expertise, and strategic collaboration. Mold makers play a pivotal role in transforming abstract concepts into tangible, market-ready products. For product developers, OEM manufacturers, and product designers, partnering with a skilled mold maker ensures not only efficiency and quality but also a competitive edge in accelerating timelines and reducing costs.

As we all know, product development is an inherently complex, multistage journey where every phase demands meticulous attention. From conceptualization—encompassing design, prototyping, functional testing, and iterative refinement—to final validation and mass production (including mold manufacturing, injection molding, secondary processing, and assembly), success hinges on seamless execution. A misstep at any stage risks cascading delays, inflated costs, and compromised quality. This underscores the need for precision-driven execution and trusted partnerships to navigate challenges and safeguard efficiency.

Key challenges of product development

Complex Designs: Increasing demand for intricate geometries and multi-material components.

Speed-to-Market: Compressed timelines to stay ahead of competitors.

Cost Efficiency: Minimizing waste and rework through precision tooling.

Scalability: Transitioning seamlessly from prototyping to mass production.

How Can a Mold Maker Add Value in The Product Development Journey?

LEARN MORE

From concept to reality, mold maker provides tailored support at every phase:

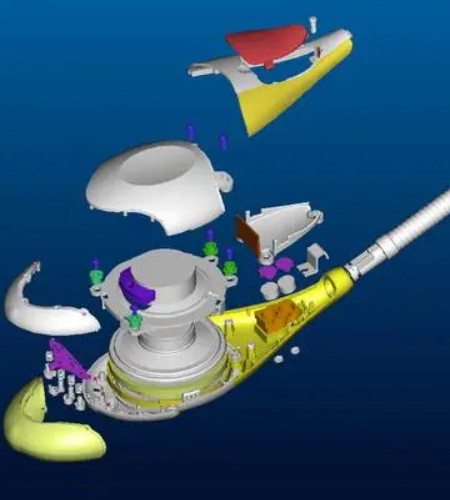

1. Concept & Design Engineering

Challenge: Translating ideas into manufacturable designs.

Mold Maker’s Role:

Design for Manufacturability (DFM): Identifying potential production pitfalls early (e.g., wall thickness, draft angles).

Material Selection Guidance: Recommending resins or silicones optimized for performance and cost.

Collaborative Problem-Solving: Refining designs to balance aesthetics, function, and tooling efficiency.

2. Prototyping & Validation

Challenge: Testing designs without delaying timelines.

Mold Maker’s Role:

Rapid Prototyping: Using silicone casting, vacuum casting, or 3D-printed molds to create functional prototypes.

Performance Testing: Validating fit, function, and durability under real-world conditions.

3. Mold Making & Tooling

Challenge: Ensuring precision and long lifetime of molds.

Mold Maker’s Role:

High-Precision Tooling: Crafting molds with tolerances as tight as ±0.005mm.

Innovative Solutions: Implementing multi-cavity molds or family molds for product parts.

Sustainability: Using durable materials to extend mold lifespan and reduce waste.

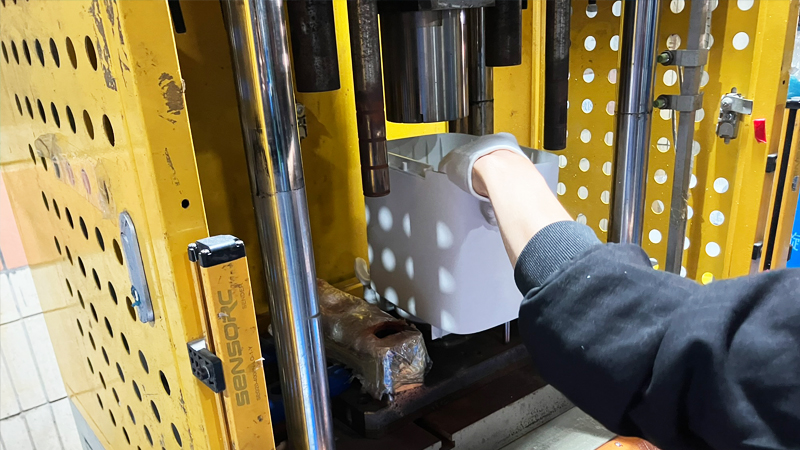

4. Production & Scaling

Challenge: Maintaining consistency and speed at scale.

Mold Maker’s Role:

Injection Molding Production: Delivering high-volume runs with repeatable quality.

Secondary Processes: Electroplating, coating, ultrasonic welding, and product assembly.

Supply Chain Integration: Streamlining workflows to accelerate time-to-market.

5. Post-Production & Refinement

Challenge: Enhancing aesthetics and functionality.

Mold Maker’s Role:

Surface Finishing: Texturing, painting, or metallization to meet brand standards.

Quality Assurance: Rigorous inspections to ensure compliance with specifications.

NEED AN ENGINEERING SUPPORT?

Why Partner with TONGDA LINK?

As a full-service mold maker and manufacturing partner, TONGDA LINK stands out by offering:

End-to-End Solutions: From product engineering, mold engineering and mold design, prototyping, rapid tooling, silicone casting, to final injection molding production, secondary process support like product surface finishing,hot melt cutting and packaging—all under one roof.

Technical Expertise: Decades of experience in plastic product manufacturing, plastic tooling, plastic injection, custom manufacturing, silicone casting, and custom tooling.

Innovation-Driven Approach: Proactive support in material innovation, lightweight, quality control, and sustainable practices.

Speed and Efficiency: Advanced technologies like rapid tooling and automated production, product assembly, custom packaging for products to slash lead times.

Collaborative Partnership: Working side-by-side with your team to align goals, troubleshoot challenges, and optimize outcomes.

The TONGDA LINK Advantages

Accelerated Launches: Reduce time-to-market by 30–50% with integrated workflows.

Cost Savings: Minimize material waste and rework through precision tooling.

Scalability: Seamlessly transition from low-volume prototyping to high-volume production.

Quality Assurance: ISO-certified processes ensure consistency across every batch.

Elevate Your Product Development with Strategic Collaboration

In an era where innovation and speed define success, mold makers are no longer just suppliers—they are strategic partners. TONGDA LINK combines technical mastery with a collaborative mindset to transform your product vision into reality. Whether you’re developing cutting-edge consumer electronics, medical devices, or automotive components, our expertise in mold engineering, injection molding production, and secondary processes ensures flawless execution at every stage.

Ready to streamline your next project?

Partner with TONGDA LINK to leverage:

Custom manufacturing solutions tailored to your needs.

Proven best practices for collaboration between mold makers and product teams.

A commitment to efficiency, innovation, and your success.

Contact us today to discover how we can accelerate your product development journey.