Making the Impossible Possible – The TONGDA LINK Way

At TONGDA LINK, we believe in actions over words. Our commitment to excellence speaks through the real-world challenges we’ve turned into successes. Here’s how we bring impossible tasks to life:

- Precision Under Pressure:

When a client needed a high-precision mold on a tight deadline, TONGDA LINK leveraged advanced CNC technology (boasting precision at 0.002mm) and a dedicated team to deliver ahead of schedule. Our swift, high-quality results kept the client’s production line moving smoothly. - Innovative Solutions for Complex Challenges:

A client once approached us with a unique design requiring specific materials to meet strict regulatory standards. Through close collaboration, our engineering team optimized the mold design to meet these requirements. The result was a mold that not only achieved compliance but also surpassed the client’s expectations. - Proactive Maintenance, Reduced Downtime:

A customer facing frequent production delays due to mold issues turned to TONGDA LINK for support. Through regular on-site inspections and preventive maintenance, we helped minimize their downtime and boost output, building a long-lasting partnership based on reliability and trust.

These examples illustrate TONGDA LINK’s dedication to precision, reliability, and problem-solving, no matter the challenge. Ready to see how we can turn your vision into reality? Let’s make the impossible possible together.

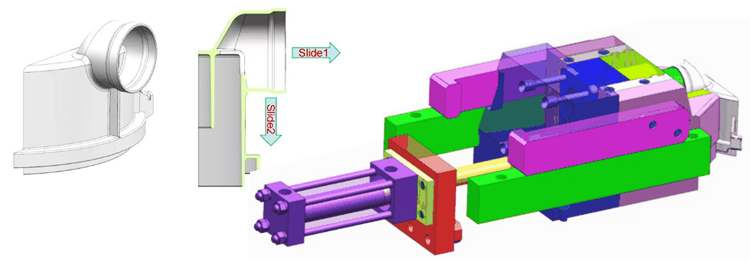

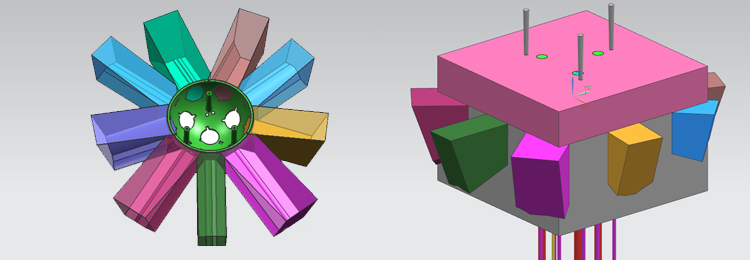

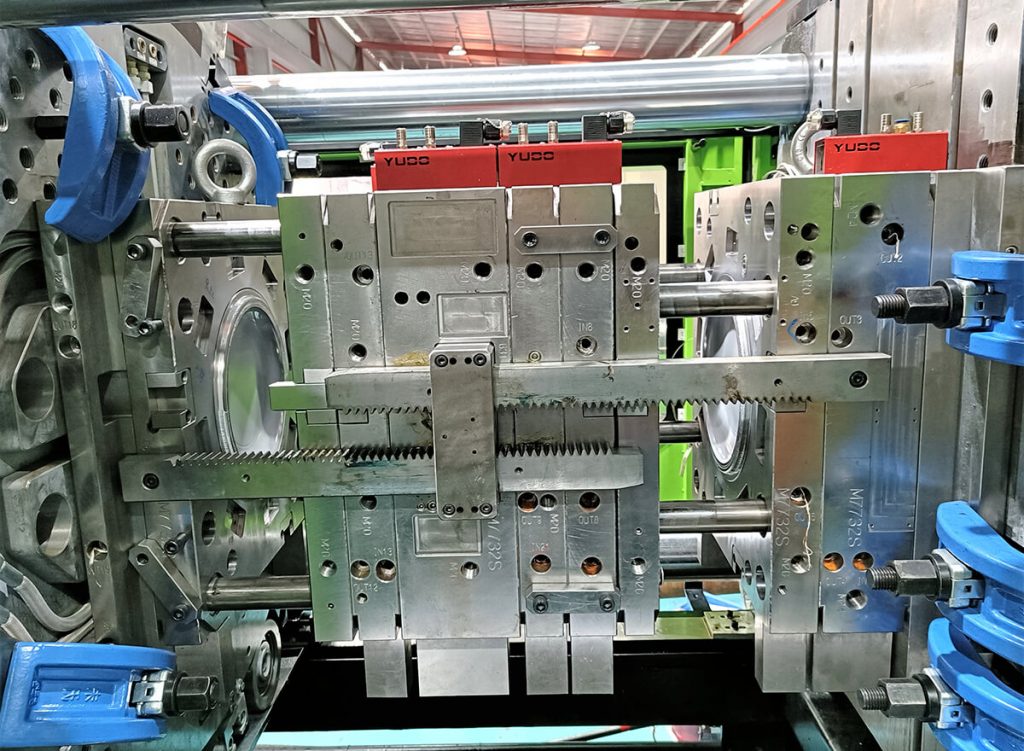

This is an injection mold design solution with a complicated mechanism. It is an automotive water tank mold with cavity 1L+1R. A total of 14 slides and two angle lifters were applied in the mold action. TONGDA LINK displays many complicated solutions for injection mold design and slider mold design. In this mold design concept, customers will obtain how to manufacture such mold.

★The plastic material is PA66+GF30.

★The mold steel cavity/core is H13-HRC48-52.

★The A & B plate of moldbase is P20.

★The slide steel is 2767-HRC54-56.

★The wear plates steel is 2510-HRC56-58.

★There are 14 slides and two angle lifters to assist mold action, including two secondary slides and two combos of secondary demoulding slides with different angles.

★This mold runs on a 650-ton injection machine.

★The lead time for T1 is 10 weeks.

★The Injection system is a two-point valve hot runner system, INCOE.

TONGDA LINK Plastic Mold-Making Services

With over 16 years of expertise, TONGDA LINK is a trusted mold-making supplier specializing in high-quality, high-performance plastic parts across multiple industries. We serve clients in the automotive, medical devices, electronics & electrical products, and industrial engineering sectors, providing solutions tailored to meet demanding industry standards and complex product requirements.

Choose TONGDA LINK for precision, reliability, and experience in delivering molds that empower your product development.

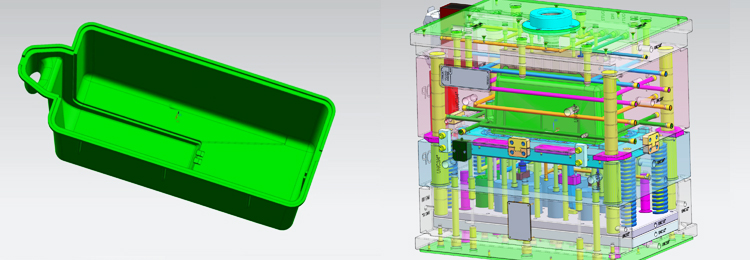

Auto running plastic housing injection mold design solutions. There are many solutions of plastic housing injection mold solutions, such as automotive lamp housing, industrial plastic housing, electronics product housing, cosmetic housing products, etc.

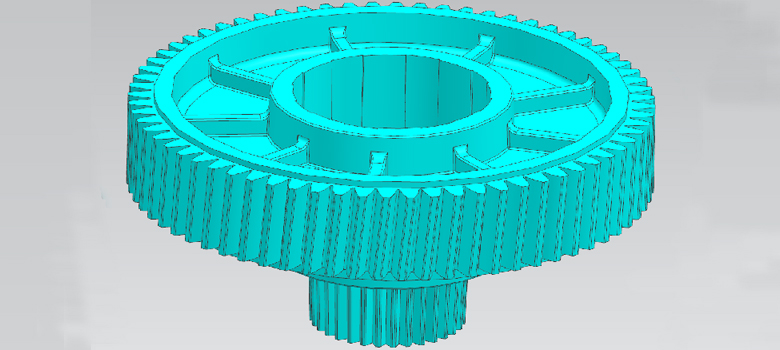

Gear Parts Plastic Mold Design

This mold project regards a helical gear injection mold design solution. For gear mold manufacturing, precision control is essential. Also, gate location in a molded gear significantly affects the gear’s accuracy, especially the runout accuracy.

TONGDA LINK Gear Mold Design Expertise

With extensive experience in designing and manufacturing spur gear, helical gear, and worm gear molds, TONGDA LINK delivers precision and reliability in gear mold production. Let’s dive into our helical gear mold design process to show how our approach ensures both quality and cost-effectiveness.

In our helical gear mold design, TONGDA LINK’s engineering team collaborates closely with clients to develop solutions that meet high-precision standards. Each step, from selecting materials to fine-tuning the mold structure, is meticulously executed, showcasing our manufacturing capabilities and commitment to quality. Our production process balances advanced engineering with cost-efficiency, making TONGDA LINK a trustworthy partner for gear mold solutions that are both high-quality and competitively priced.

Choose TONGDA LINK for gear molds that exceed expectations in performance, reliability, and value.

More details GET A QUOTETONGDA LINK Custom Plastic Injection Molding Service

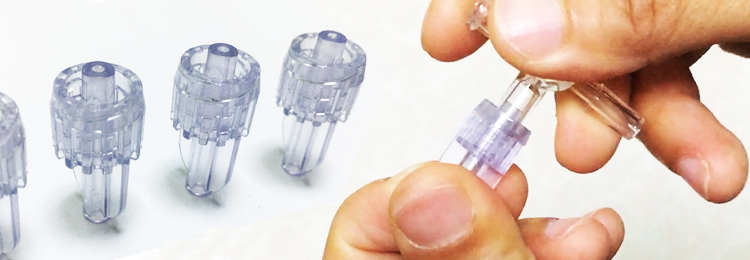

PVC medical device Luer connector

TONGDA LINK Cleanroom Injection Molding for Medical and Life Science Applications

TONGDA LINK specializes in cleanroom injection molding solutions tailored for medical devices, laboratories, and life science products. Our advanced cleanroom facilities and expert mold design capabilities allow us to meet the stringent hygiene and quality standards these industries demand.

We offer a wide range of injection mold and cleanroom production solutions for critical medical components, including Luer connectors, medical tips, centrifuge tubes, Y connectors, syringes, and stainless steel needles. Our team works closely with clients to develop optimized molds and processes, ensuring reliable, high-quality production at every step.

Count on TONGDA LINK for innovative, precision-driven solutions that support safe and effective medical and life science products.

More detailsTONGDA LINK Plastic Injection Molding Design Guidance

Essential Guidance for Plastic Injection Molded Part Design – TONGDA LINK Expertise

For plastic product engineers, understanding the fundamentals of plastic injection molding is crucial to avoid common issues like sink marks, warping, short shots, and non-functional parts. Ignoring these design rules can compromise product quality and functionality.

At TONGDA LINK, our experienced mold engineers work closely with customers at the start of each project. We perform a detailed Design for Manufacturing (DFM) analysis to evaluate the plastic part design. This report highlights areas where adjustments can improve manufacturability, reduce potential defects, and streamline production. By addressing design concerns from the mold manufacturing perspective, we ensure that each product moves seamlessly from design to production.

For insights into effective plastic injection molded part design and injection mold guidelines, rely on TONGDA LINK’s expertise to create parts that perform reliably from the start.

More detailsSecondary Demolding Plastic Mold Design

Advanced Secondary Demolding Plastic Mold Design Solutions by TONGDA LINK

TONGDA LINK excels in secondary demolding mold design, addressing the needs of complex plastic products that require intricate demolding mechanisms. With extensive experience in sophisticated mold design, we tackle challenging projects that demand precise, multi-step demolding solutions.

Our engineers create and showcase a range of innovative mold design solutions to help customers understand TONGDA LINK’s mold manufacturing capabilities, especially for difficult and intricate plastic components. These designs demonstrate our skill in secondary demolding mechanisms, ensuring high-quality production for parts with complex shapes or undercuts.

Trust TONGDA LINK for reliable, advanced mold design solutions that meet the demands of even the most complicated plastic products.

More detailsCollapsible Core Plastic Mold Design

Collapsible Core Plastic Mold Design Solutions by TONGDA LINK

TONGDA LINK offers specialized solutions for collapsible core plastic mold designs, ideal for products with inner undercuts that demand precise demolding. Our expertise in collapsible core mechanisms ensures efficient and seamless demolding, even for complex geometries.

We provide a range of collapsible core mold design solutions to help customers understand TONGDA LINK’s capability in handling intricate part requirements. Each design is tailored to ensure smooth, damage-free demolding, supporting the production of high-quality, undercut-featured parts.

For challenging part designs with inner undercuts, TONGDA LINK’s collapsible core solutions offer the precision, reliability, and expertise your project needs.

More details2K Injection Mold Design Solutions

2K Injection Mold Design Solutions for Automotive Dashboards by TONGDA LINK

TONGDA LINK specializes in 2K (two-component) injection mold design solutions tailored for automotive dashboards and other complex multi-material components. With extensive experience in 2K and 3K injection mold designs, we support high-quality, double injection molding for automotive and other demanding projects.

Our team provides a variety of 2K/3K mold design solutions for customers, showcasing our capability to manufacture parts with multiple materials or colors in a single mold cycle. This process is ideal for dashboards and similar components, where a combination of aesthetics, functionality, and durability is essential.

With TONGDA LINK’s expertise in 2K injection molding, you gain access to innovative, precise, and reliable manufacturing solutions for sophisticated, multi-material products.

More detailsTONGDA LINK Stack Mold Design Solution

TONGDA LINK Tooling Custom Manufacturing Technology Resources Center

Design for manufacturing of plastic injection mold

General mold for reference

| Product Name | Professional OEM custom products of plastic injection molding and molds |

|---|---|

|

Design software

|

Solidworks/PROE/UG/CAD

|

|

Mould base

|

LKM, HASCO, DME

|

|

Mould material

|

S136/2344/718/738/NAK80/P20

|

|

Plastic material

|

PVC/PA66/PC/PE/POM/PMMA/ABS/TPU/TPE/PE/PP, etc

|

|

Mould life

|

300,000-500,000shots

|

|

Cavity

|

Single/Multi Cavity

|

|

Payment terms

|

T/T,Paypal,Though credit card on Alibaba and so on

|

|

Package

|

Standard wooden case or steel frame or according to customer’s requirement

|

|

Delivery terms

|

UPS,DHL,FEDEX,By SEA or according to customer’s requirement

|

|

Lead time

|

15-35days

|

|

Certification

|

ISO9001:2015, IATF16949, ISO13485

|